You want to strengthen your welding work. One of the best options is to automate your laser welding. Unlike traditional TIG, laser welding produces deep and narrow welds with minimal heat input, reducing distortion and thermal stress. In addition, it offers higher welding speeds and superior precision, making it an ideal solution for thin-walled or heat-sensitive component.

At Mecanext, we have witnessed how this transformation has changed production floors. This guide is going to be your manual. We are going to take you through the steps on how to automate laser welding processes, from the very first idea to a working system.

Why Should You Automate Your Laser Welding?

Before you learn the “how,” it is necessary to know the “why.” Laser welding automation is a powerful tool. The improvements in product quality and output help you to keep up the competition. This is confirmed by studies on the modern trends in welding process automation.

Here are some of the main advantages you can expect:

- Higher Accuracy: Robots and machines are not like humans who get tired and make mistakes. They have the capability of programming the welding path and speed exactly the same way all the time. Thus, every piece has the same good quality of welded joints.

- More Production: An automated system is able to work much faster than a person. It can also operate 24 hours a day, 7 days a week. This dramatically increases your capacity for manufacturing.

- Reduced Costs:Initially limited by high costs and CO₂ laser technology, automated fiber laser welding has become affordable for manufacturers. It help reduce the high cost of manual welding labor and have less material waste from bad welds. That’s not all; there will be fewer parts that need fixing.

- Safer for Workers: Laser welding emits very bright light and releases toxic fumes. Automation helps you by removing the operator from the dangerous area. The process runs in a safe and closed chamber.

Choosing the Automation Path

If you have chosen to automate laser welding processes, there are only three main methods that you have. The choice is made depending on your manufacturing volume, complexity of parts, as well as your budget. You can select between industrial robots, collaborative robots, or CNC systems.

Fully Automated Robotic Cells

A fully automated robotic cell is a system that integrates a fast 6-axis industrial robot. These robots are placed in a fully enclosed safety cell. This is recommended setup for mass production and complex parts.

They are very efficient for high-volume and low-mix manufacturing. You can think about car assembly lines. Each day, the same part is welded hundreds of times. Their main features are maximum speed, high repeatability, and they are Ideal for large parts.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are a new and more advanced option. With them, you are allowed to work safely next to a human being. They do not need large cages. This makes cobots suitable for small or flexible production lines.

Cobots are the best fit in small and medium businesses. Moreover, they are also suitable for jobs with a high mix and a low volume. You will be required to change the setups with the jobs often. Their main pros are flexibility, a lower initial cost, and easier programming.

CNC (Computer Numerical Control) Systems

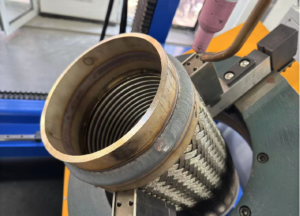

CNC systems use a gantry or cartesian frame to move the laser head. The head moves along a very precise, pre-programmed path. The part usually stays still while the laser moves over it.

These systems are the best choice for flat parts or round parts. They excel at making very precise patterns and very simple programming. Their strengths are extreme accuracy, low cost and their highly rigid structure.

| Feature | Robotic Cell | Cobot System | CNC System |

|---|---|---|---|

| Best For | High Volume, Low Mix | High Mix, Low/Med Volume | High Precision and Volume |

| Speed | Very High | Medium | Very High |

| Footprint | Large | Small / Flexible | Small |

| Initial Cost | High | Medium | Low-Medium |

| Flexibility | Medium | High | Low |

| Safety | Requires full enclosure | Works alongside humans | Simply Uploading Welding Parts |

Your 3-Step Roadmap to Automation

Learning about automated laser welding processes is a journey. Following a structured plan enables you to avoid common mistakes. Also, it ensures the project is successful. Here is a five-step roadmap to guide you through this.

Step 1: Figure Out Your Welding Needs

The first step is to check if your project is suitable for automation. Look at the part carefully. Is the material suitable for laser welding? Is the weld joint made in such a way as to allow robot welding or machine welding access? Do all parts that come to the welding station come the same way and thier size range? What is my welding part thickness?

Here’s an expert tip: Match your actual welding needs.

If your weld path is complex or requires multi-axis motion, a robotic welding system or cobot may be the right choice.However, if your parts only require circular seam welding, then using a cobot might be overkill — it costs more and requires more complicated programming.

In this case, a dedicated CNC-type automatic welding machine designed for circular welds would be a smarter option. It’s simpler to operate, more efficient, and offers consistent welding quality.

Most improtantly, automated laser welding is faster but it’s more suitable for thin-walled welding parts. If your welding part thickness is more than 8mm, then it’s not recommened for automated laser welding. And if the welding seam width is wider, it’s also not suitable for laser welding.

Before you invest in the machine, ensure that you choose a most

Step 2: Calculate Your Return on Investment (ROI)

Compare the cost of the machinery with the amount that you are going to save. The savings will come from reduced labor, increased output, and improved quality.

Automation Laser Welding is no longer a luxury. Even some small shops can afford it to optimize their welding presicion and welding speed.

For example, the leading choice is fiber lasers as these are widely available today. And the cost of a set of automatic fiber laser welding machine, not the robot and cobots type can pay back its cost within one year. That’s why we are seeing some rise of the usage of automation laser welding.

Step 3: Integration & Programming

The best automated laser welding machines are compact and can be easily integrated into your production line without taking up much space.

In contrast, poorly designed machines often have messy wiring and bulky structures, which not only make maintenance difficult but also reduce overall system reliability.

In addition, it’s important that the automated laser welding machine is easy to operate. For the robot welding or cobot welding, the programming still needs experienced welder. However, some circular type automatic laser welding machine only needs simple operation after setting the parameters. Even some women without progessional welding knowledge can operate the machine. In this way, it can help you further reduce manual labor cost.

Other Factors to Consider:

–Safety is the highest priority. An automated laser welding system must have a light-tight enclosure. This is a physical barrier that blocks the powerful laser beam. It needs a simple that shut off the laser if they are opened.

–The reliability quality of the autoamtic laser welding machine and the supplier. It’s not a one-time purchase. You’ll be using the automatic laser welding machine for years. It’s important that the machine quality is reliable and the supplier is both prefessional and provides continuous after-sales support.

–Standard operating procedures (SOPs). You should also create standard operating procedures (SOPs). These documents explain how to properly and safely run the machine. MecaNext provides detailed SOP documents for our customer to ensure that the operator on site can know how to operate machines step by step.

The Future of Automated Laser Welding

Automated laser welding technology keeps growing and getting better. The new innovations are making such systems quicker and more reliable. By being aware of these trends, you can make an informed investment for the future.

AI and machine learning are changing the game. Systems can now use AI to watch the weld. They adjust parameters in real time for optimal quality. This reduces the need for human supervision.

Advanced sensor integration is another huge trend. As described in reports on Innovations in Laser Welding Technology, inline monitoring with cameras and sensors has become the new standard. These sensors can detect defects as they occur.

These intelligent systems are a major part of the Industry 4.0 “smart factory.” They can be plugged into a factory-wide network. They can store data for full traceability. As explained in articles about the future of laser welding in automation, this combination of AI and sensors is guiding the industry forward.

Conclusion: Your Path to Automated Excellence

To automate laser welding processes is a strategic move. It can deliver huge returns. It boosts speed, quality, and safety on your production line. The path to success is through careful planning. You need to choose the right type of technology that is suitable for you. You must also follow a step-by-step implementation plan.

The journey begins with a simple evaluation of your present method. Understanding your parts, volume, and objectives will help you build a strong business case for automation.

Should you wish to know how to automate your laser welding processes, our team can help. We can design the perfect automation welding solution.

Frequently Asked Questions (FAQ)

How much programming skill is needed to run an automated laser welder?

It depends on the system. Modern cobots often use simple, graphical interfaces. These require very little programming skill for basic tasks. Traditional industrial robot cells need operators with more specialized training. They need to know robot programming and PLC logic.The CNC type autoamtic laser welding machine for circular welding can also be very simple. Once setting parameters, even man without welding skills can operate the machine.

Can I automate welding for small batches of different parts?

For the automated Tig welding, our automatic welding machine is perfect for small batches of different parts because the chuck can be ajusted in sizes. This makes them great for high-mix, low-volume production. You can switch between different parts often.

What are the most important safety considerations for automated laser welding?

The top priorities are protecting people from the laser beam and harmful fumes. This means using a laser-safe enclosure with interlocked doors. You also need proper ventilation and fume extraction. Anyone near the area should have certified laser safety glasses.

Can I use my existing handheld laser welder in an automated setup?

Generally, no. Handheld welders are made for manual control by an operator. To automate laser welding processes, you need a dedicated laser source and welding head. These components have input/output ports. They communicate with a robot or PLC for precise, automated control.