So, you want to know about the nature of TIG welding, whether it is manual or automatic? The simple answer is: it’s both. TIG welding is not one set of techniques; it is a broad spectrum of activity. It can be a skillful manual work or a fully automated factory process.

Asking if TIG welding is manual or automatic is a good sign. This question means that you want to be more informed about the process. The choice depends on what you need.

In this guide, we will introduce you to the three types of TIG welding. We will cover manual, semi-auto, and fully automatic. When you finish reading, you will know which technique is suitable for your project or business.

The Manual TIG Welding: The Traditional Way

Most people assume that TIG welding is a manual process. It’s known to be the most accurate process in welding and can create beautiful joints. Many people see this process as the supreme welding art.

What Is Manual TIG Welding?

Manual TIG welding is not only a metalwork technique but also an art. This is simply the most creative way to join metals together. Compared to other welding methods, TIG welding is known for excellent aesthetics, precision, and repeatability. It is even seen as the best welding method.

Features of Manual TIG Welding

Manual control creates a certain level of precision. The welder is in charge of every section of the joint. This is ideal for welding thin metals, complex joints, or critical parts where failure is not an option.

- Joining Diverse Metals: A talented welder is able to TIG weld more metals like stainless steel, aluminum, titanium, and copper alloys than with almost any other process.

- High-Quality, Clean Welds: TIG welding is very clean and does not create sparks or spatter. The welds made are strong, beautiful, and the final product may need little to no cleanup at all.

The Challenges of Going Manual

Although it is fascinating, manual TIG has some shortcomings. These issues must be understood.

- Difficult to Learn: It takes a lot of time and practice to become good at manual TIG. Learning the coordination can take hundreds of hours.

- Time-Consuming Process: It is a slow process. You add filler metal at a lower rate than with methods like MIG welding.

- Welder’s Fatigue: The amount of focus required can be exhausting. A welder may become fatigued by the end of the day. This can affect the quality of the welds.

Using Innovation: Automated TIG Welding

Because manual TIG takes more time, many businesses have been looking for ways to make it faster. This is where we give the response to part of the question: “Is TIG welding automatic?” Yes, and it comes in two main types.

Automated TIG welding employs technology to the extent that certain or all tasks associated with the welding process are done by machines. This not only increases the speed of the process but also ensures that each weld is done correctly and consistently.

What is Semi-Automated TIG Welding?

Semi-automated TIG represents the middle way. The welder is still in charge but the machines take care of the repetitive parts of the job. This helps make the welder’s job easier and faster.

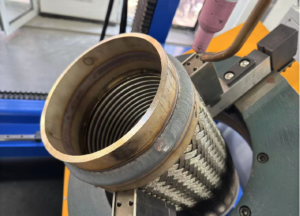

One of the best examples here is the orbital welder. The machine has a special head that clasps around the pipe. The TIG torch then travels around the pipe all by itself to create a perfect weld. The welder only sets it up and watches the process.

Other systems, like automatic wire feeders, help by feeding the filler rod for the welder. This frees up one of the welder’s hands. As experts in transitioning to semi-automated TIG welding explain, these systems bridge the gap between pure manual skill and full automation.

What is Fully Automatic (Robotic) TIG Welding?

Fully automatic TIG welding is when the whole job is left to a machine. A robot or a computer-controlled system does the weld from start to finish. A human operator loads the part and starts the program, but the robot or machine does the welding.

A common robotic TIG setup consists of:

* A robot arm to manipulate the torch.

* A controller, which is like the robot’s brain.

* A TIG power source and torch.

* A fixture to hold the part firmly in the same place every time.

The benefits are obvious. You achieve great repeatability, allowing you to produce thousands of identical parts. In addition, the speed goes up a lot. It removes the human operator from the heat and fumes of the weld zone. This is a real automation welding solution for high-volume manufacturing.

Manual vs. Semi-Auto vs. Fully Auto TIG: A Head-to-Head Comparison

So, how do you decide between manual, semi-automatic, or fully automatic TIG? The “best” method totally depends on the exact job you are going to do.

This table gives you a clear, side-by-side view of the three options. It helps you understand the trade-offs in skill, speed, cost, and flexibility. Understanding this comparison will make you aware of whether manual or automatic TIG welding suits you.

Summary Features Comparison Table

| Feature | Manual TIG | Semi-Automated TIG | Fully Automated (Robotic) TIG |

|---|---|---|---|

| Best For | Custom fabrication, repair, art, critical one-off welds | Repetitive tasks like pipe/tube welding, medium-volume production | High-volume, repeatable production runs |

| Skill Level | Very High | Medium | Medium to High (for programming), Low (for operation) |

| Speed | Slow | Medium | Very Fast |

| Consistency | Operator-dependent | High | Extremely High |

| Flexibility | Very High | Medium | Low (for a specific setup) |

| Initial Cost | Low | Medium | Medium to High |

| Weld Quality | Potentially Excellent | Consistently Excellent | Consistently Excellent |

Practical Decision-Making: Choosing the Right Option

Now let’s turn the theory into practical action. This guidance will help you scrutinize your own situation. Refer to the following scenarios to identify the kind of TIG welding that will suit you most.

Choose Manual TIG If…

The classic solution for flexibility and low startup cost is manual TIG. It is the best option in certain scenarios.

- You are a hobbyist, an artist, or run a small custom shop.

- Your work involves unique, one-of-a-kind parts or complex repairs on existing items.

- Your new equipment budget is limited. A basic TIG welder is much cheaper than an automated one.

- The parts you weld change all the time in shape, size, and thickness.

Consider Semi-Automation When…

Semi-automation is a great step up. It helps you make more parts without losing any of the quality TIG is known for.

- You want to speed up the jobs that you do repetitively.

- You are welding a lot of pipes or tubes. An orbital welder or CNC type automatic welding machine witha chuck will be worth the money in speed and quality.

- You want to cut down on welder fatigue for medium-sized production runs. An automatic wire feeder can make a big difference.

Invest in Full Automation For…

Full automation is a huge investment. However, it gives great returns when used for the right applications. It is the best choice for mass production.

- Your intention is to manufacture thousands of absolutely identical components without any variation.

- Absolute consistency is required, such as in the aerospace, automotive, or medical industries.

- Your long-term goal is to reduce labor costs per part.

Before you invest, there are 4 Things to Consider Before Automating TIG Welding. You must think about part volume, how consistent your parts are, and the return on investment. While a manual welder might travel a few inches per minute, an automated TIG system can often achieve speeds 2 to 4 times faster. This can drastically change how many parts you can produce in a day.

The Continuous Evolution of TIG Welding: Making Work Easier

The world of TIG welding is fast-moving. Automation is also becoming more flexible and easier to use thanks to technology.

New collaborative robots, or “cobots,” work closely with people in a safe manner. And CNC autoamtic welding machine with a rotated chuck can also be affordable. Welding robots or the automated welder are now being fitted with advanced sensors, making them capable of seeing and adapting to small changes in the part. This helps to automate jobs that were once possible only with a human eye.

These trends are reshaping the choice between manual and automatic TIG welding. Companies like Mecanext drive this change. We help businesses utilize advanced technologies for improving their production and boosting efficiency. The future is all about combining human skill and machine precision in the best way.

Conclusion: A Spectrum of Possibilities

So, is TIG welding manual or automatic? As we’ve seen, it’s not a simple yes or no question. TIG is an adaptable process that has a solution for nearly every problem.

It can be the artisan’s tool for creating a one-of-a-kind sculpture. It can also be the factory’s workhorse, producing thousands of perfect parts a day. The right choice lies on a spectrum, from fully manual to fully automatic.

Frequently Asked Questions (FAQ)

1. Is TIG welding harder to learn than MIG welding?

Yes, TIG welding is generally harder to learn. It has a steeper learning curve because it requires two-handed coordination and foot pedal control. As welding experts note, the TIG process can be automated, but the manual skill takes significant practice. The majority of welders start with MIG and then move to TIG.

2. Can you automate TIG welding on aluminum?

Absolutely. Automated TIG welding is often used for aluminum, especially in high-volume production. Aluminum can be tricky due to its properties, but automation provides the precise control needed. It requires an AC power source and very stable settings, which robots and machines handle very well.

3. What is orbital TIG welding?

Orbital TIG welding is a type of semi-automated welding. In this process, the TIG torch automatically rotates 360 degrees around a pipe or tube that is held still. It is used in industries like food processing and pharmaceuticals where perfect, smooth welds are needed to ensure cleanliness.

4. Do you still need a skilled welder for automated TIG welding?

Yes, a skilled welder is essential for robot welding because its programming need skills. While the robot performs the weld, an expert is needed to program the robot, set up the job, and solve any problems. Their deep knowledge of welding is what allows them to tell the robot how to make a perfect weld.

But for the automatic welding machine with a computer-controlled system and chuck, its programming can be easier. And once programming set up, operate 2-3 machines at the same time.

5. What is the main disadvantage of manual TIG welding for production?

The biggest disadvantage is its slow speed. Manual TIG has a low deposition rate, meaning it takes a long time to add filler metal and finish a weld. This makes it much less productive for manufacturing many parts compared to MIG welding or any form of automated TIG. This slow speed directly impacts cost and how quickly projects can be finished.