Our 1440-T Automatic Tig Welding Machine is designed for Tig precision circular welds on pipes, tubes, metal hoses, bellows and cylindrical components. Featuring advanced automated welder, it ensures consistent, high-quality welds while boosting efficiency and reducing manual labor cost.

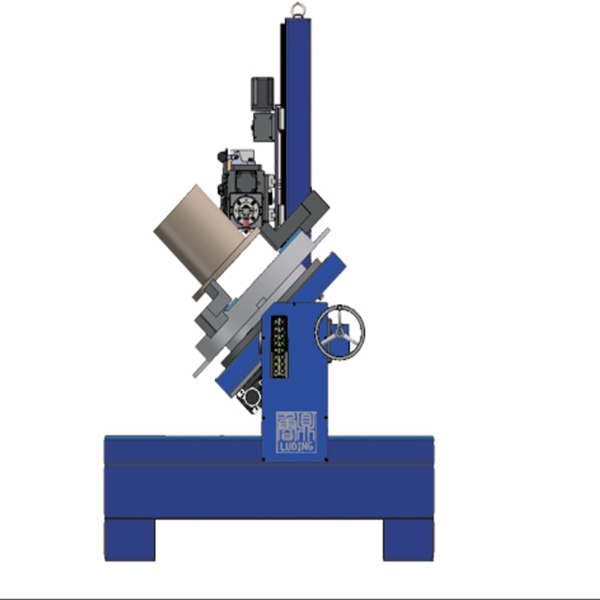

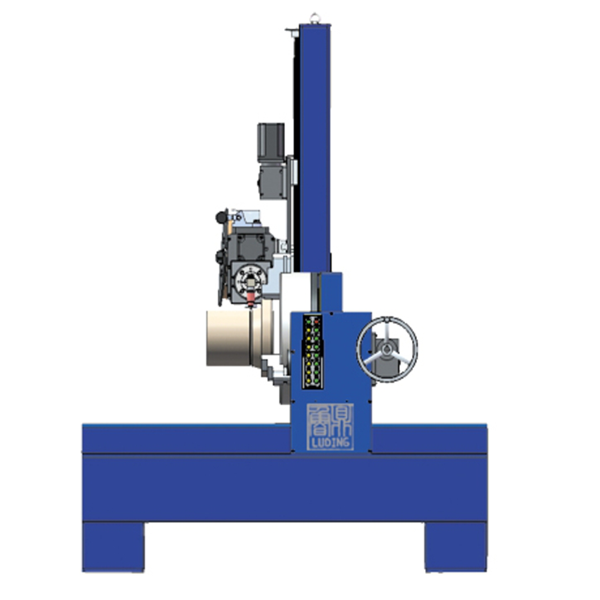

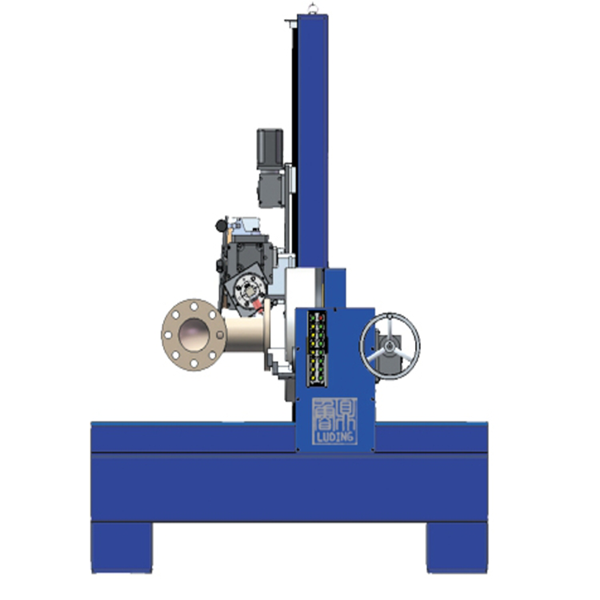

The integrated welding arm, positioner, and torch angle adjustment mechanism enable multi-position and multi-angle adjustments, ensuring precise and flexible welding.

| Model | H1440-T Automatic Welding Machine |

| Joint Type(s) | Pipe-to-pipe, pipe-to-high-neck flange butt-joint, pipe-to-flange corner joint, elbow-to-flange corner joint |

| Three-jaw self-centering chuck | Central hole diameter: Φ 138mm; Clamping outer diameter: Φ20 ~ Φ 400mm; |

| Positioner | Positioning motion range: 0~90°; Rotation radius: 300mm. |

| Oscillator | Oscillation width: 0~40mm; Oscillation speed: 0~20mm/s; Oscillation type: Pendulum; Oscillation dwell time range: 0~5s |

| Arc voltage controller | Standard slide track range: 0~40.0mm; Standard slide speed range: 0~6mm/s; |

| Automatic wire feeder | Suitable for wire diameter: Φ 1.0mm |

| TIG torch | LD400 water-cooled TIG torch; Angular motion range: 0~90° |

| Control Terminal | Color touchscreen control terminal |

| Storage capacity | Able to store 30 sets of welding procedures |

| Power source | Panasonic YC-400TX TIG power source (optional extension: Panasonic hot wire power source) |

| Manipulator arm travel distance | X×Y×Z : 800mm×700mm×30mm; x-axis effective travel distance: 400 |

| Overall dimensions L × W × H (mm) | 1300×1800×1750 (excluding control cabinet) |

| Input power/ voltage / frequency | Panasonic power source: 30KW/380V/50Hz; Control cabinet: 1.0KW/220V/50Hz |

Our advanced Tig automatic welding machine is designed for high-precision, consistent, and efficient welding, making it ideal for industries requiring superior weld quality.

Our cutting-edge automated welding solutions help increase productivity, reduce defects, and improve overall welding efficiency across industries like automotive, aerospace, shipbuilding, and metal fabrication.

Key Features:

Ideal for industries requiring high-precision automated welding, our system guarantees consistent weld quality and increased production efficiency.

Our automatic welder is designed with an intuitive and user-friendly interface, ensuring seamless operation and enhanced efficiency.

Our advanced welding automation enhances productivity, reduces human error, and ensures high-quality, repeatable welds for industries like automotive, aerospace, shipbuilding, and metal fabrication.

Experience next-level welding efficiency with our intelligent, user-friendly automated welding system! Designed for precision and versatility, it’s perfect for welding metal hoses, pipes, bellows, tanks, and any circumferential weld of the industrial components.

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province