What to Consider Before Buying an Automated Welding Machine

Investing in an automated welding machine can revolutionize your production process. It’s also the future of welding industry. But there are many...

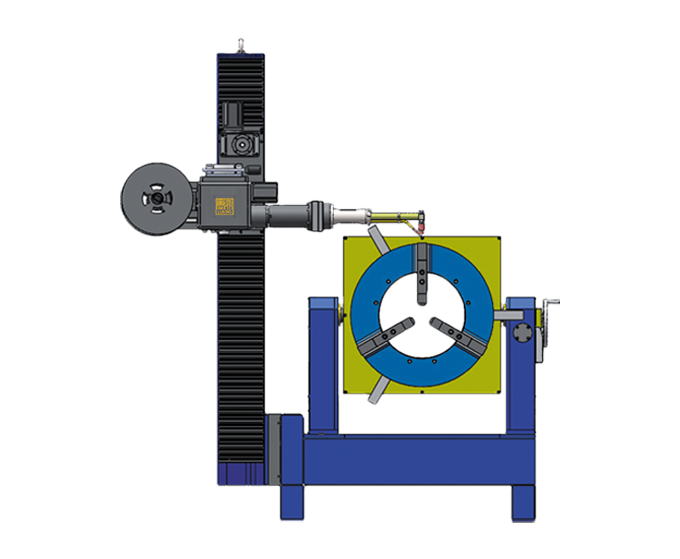

For various short pipe welds on materials like carbon andlow-alloy steel. Ideal for corner and circumferential seams.

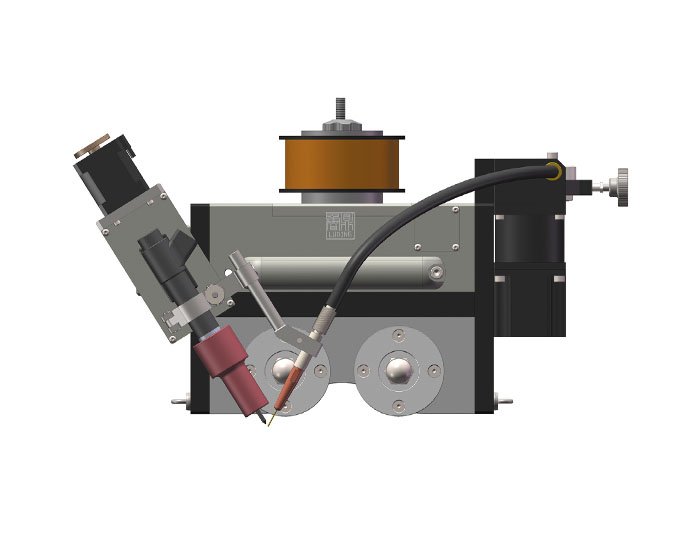

No matter the arc starting point, it automatically adjusts the nozzle height in real-time, unaffected by the workpiece's elliptical shape.

Achieves a larger welding area, maintains a constant temperature in the welding zone, and results in better weld formation.

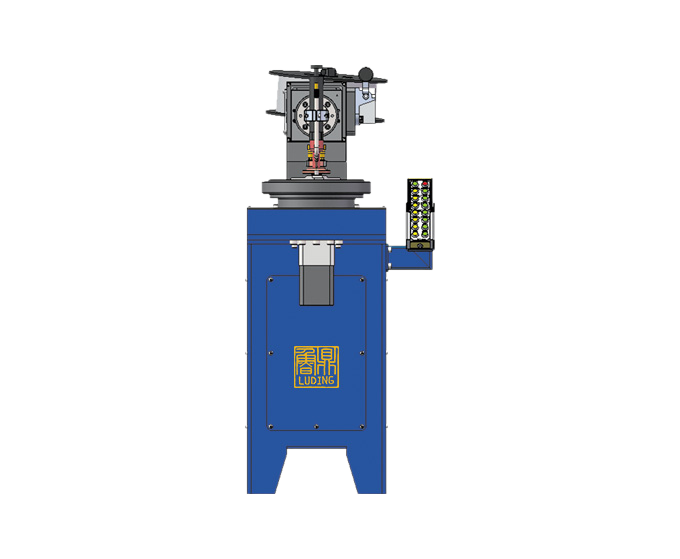

Fully automatic layered welding for thick-walled workpieces, including root pass, fill, and cap, capable of welding up to 8 layers without manual intervention.

20 years of optimization, stable structure, and forced water cooling. Capable of continuous operation for 8000 hours without abnormalities during non-stop testing.

Can store up to 30 sets of circumferential welding and 10 sets of longitudinal welding settings for easy recall based on workpiece specifications.

One-button operation for fully automated welding, featuring automatic wire retracting and pulsed wire feeding. One machine is equivalent to 1.8-2.5 skilled welders.

Single-side welding with double-side formation, welds can be verified through pressure testing and NDT (Non-Destructive Testing).

Electric 7-axis robotic arm + full-angle electric positioner, capable of performing circumferential and longitudinal welding at any angle.

Become a world-class provider of automatic welding solutions.

To set the benchmark for excellence in automated welding, delivering precision and reliability that exceed expectations.

Customer-centric, driven by dedicatedindividuals, united and efficient, withsincere passion.

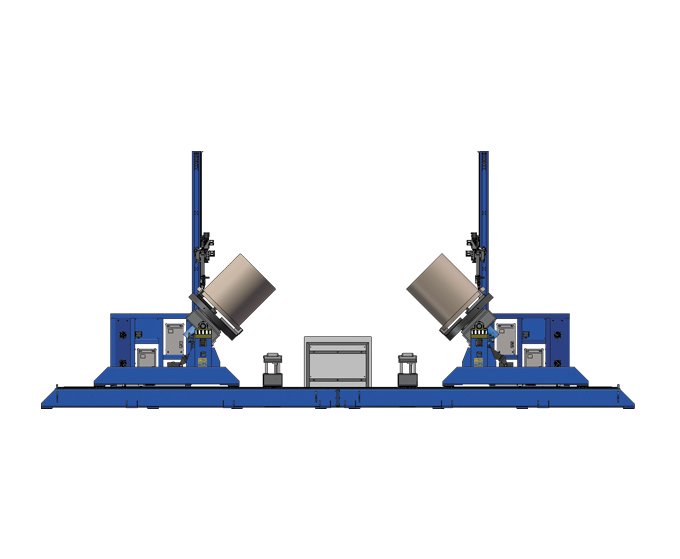

Welding Automation Solutions by Mecanext are specialized in handling circular fillet welds, butt welds, and straight seams, with no manual intervention required. These solutions enable multi-layer fully automated welding of thick-walled workpieces (root pass + fill pass + cap pass

Investing in an automated welding machine can revolutionize your production process. It’s also the future of welding industry. But there are many...

Overcoming the Limitations of Manual Welding in Expansion Joint Production Compared with automated Tig welding, the expansion joint industry faces...

Automating Nozzle Welding of Pressure Vessel with TIG Technology In the field of pressure vessel fabrication, most manufacturers have adopted automation for circumferential...

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province