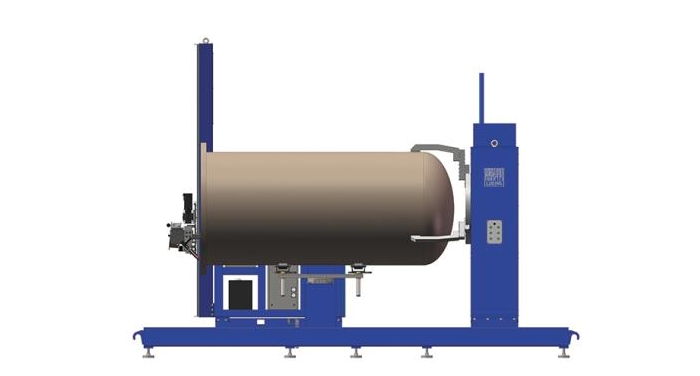

For various tank welds on materials like carbon and low-alloy steel ldeal for tank end cap circumferential seamsand barrel longitudinal seam.

Optimized for tanks up to 5000mm in length anddiameters ranging from 1000 to 3000mm.

| Model | HZK1220F-TD |

| Welding Type | Cylinder head circumferential weld, straight seam of cylinder body, and internal/external angle welds of cylinder body |

| Chuck | Three-jaw electric self-centering chuck; center hole Φ515mm; supports outer diametersΦ400~Φ1200mm; |

| Main Shaft Box | Electric shaft rotation, suitable for different workpiece lengths |

| Support | 180° rotation, lift adjustment; suitable for Ø400~Ø1200mm |

| Welding Torch Oscillation | Oscillation width 0~20mm; oscillation speed 0~20mm/s; pause time at edges 0~5s |

| Arc Length Tracking System | Tracking range 0~40.0mm; tracking speed 0~6mm/s; tracking precision 0.2mm |

| TIG Automatic Wire Feeder | Suitable for wire diameter 1.0mm |

| Welding Torch | LD27 water-cooled TIG welding torch; angle adjustment 0~90° |

| Controller | Color touchscreen controller |

| Storage Capacity | 40 welding processes (30 circumferential + 10 straight seams) |

| Welding Layers | Automatic multi-layer welding |

| Welding Power Source | Panasonic YC-400TX TIG welding power source (optional Panasonic hot-wire TIG power source) |

| Operating Stroke (mm) (X×Y×Z) | 3000×1200×30 |

| Overall Dimensions (mm) | 4500×2800×3500 |

| Input Power Supply | Welding power source 30kW/380V/50Hz, control system 1.0KW/220V/50Hz |

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province