To stay in the race for improved productivity and quality, many companies are investing heavily into automation systems. This incentive results in most manufacturers automating their production lines. The decision of what type of automation to implement is often complex.

This manual is aimed at helping you learn the most popular automatic welding processes. We prioritize a brief and clear overview so that you can find a solution that matches your project the best.

First of all, we will tell you what automatic welding is. We will then describe the most well-known technologies. Following this, we will compare them. In the end, we will suggest you a simple decision flowchart.

Automatic Welding: The Basics of Becoming Familiar with Automation Levels

People mostly picture a machine working entirely on its own when they hear the term “automatic welding”. But automated welding actually includes various levels of automation. It is vital to the making of wise decisions.

For example, there is orbital welder. You have to put the welding head on the part and then the orbital welder will rotate around the welding parts and finish the automated welding. It’s portable and convenient. But it’s limited in welding thicker product.

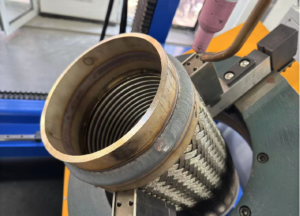

The next level is hard or fixed automation with a chuck and programmable interface. This is made for mainly circular welding seam. It is most effective for the mass production of identical components. Imagine a machine that only welds similar parts with different sizes all day. This is one of the classic choices of automatic welding process for pipes, joints, metal hoses, expansion joints, flow meters etc.

The last one is robotic welding. When a welding process is being done automatically by a robot, we speak of robotic welding. This provides a broad range of applications. Along with the user-programmable options, impressive flexibility is offered by the robotic arm that can perform complicated weld paths. It can also quickly switch between parts. This is a perfect example of a process that is good for increased volumes with many variations.

The Most Common Types of Automatic Welding Process

A few welding processes can be done automatically. Each method has its individual advantages. Your choice will depend on the type of material used, production speed, and quality. Let’s first see the most common ones.

Automated Gas Metal Arc Welding (GMAW / MIG)

What it is: GMAW stands for Gas Metal Arc Welding, which is also known as MIG welding. This welding type employs a wire that continuously feeds. It furthermore uses a shielding gas that protects the weld from air contamination.

Why it’s automated: MIG welding is already quick. Automation makes it much faster and ensures its reliability. Robots are able to maintain the ideal travel speed and angle of the gun. This keeps errors to a minimum and raises production.

Best-Fit Uses: This is a common process in a variety of industries. Constructors, manufacturers of cars, and metalworkers are just some of the places where you can usually find it.

Pros & Cons:

* Pros: High welding speeds, versatility in thickness of materials, less expensive equipment costs.

* Cons: Not suitable for very thin materials, may produce spatter if setup is incorrect.

Automated Gas Tungsten Arc Welding (GTAW / TIG)

What it is: GTAW or tungsten gas arc welding uses a tungsten electrode that is not consumed during the process. A separate filler wire can be added if needed. TIG welding is characterized by the excellent quality of welds as well as welding direction.

Why it’s automated: Manual TIG welding can take a long time and also require a highly skilled operator. Both problems are overturned by automation. High-precision robot machines go faster and work better than skilled workers do. In addition to this, their performance is consistent throughout the time. For this reason, it is a choice of many industries involving the different types of automatic welding process for high-quality products.

Best-Fit Uses: This process is very suitable for industries where the quality of the product is the most crucial thing. Such sectors are: aerospace, medical devices, food-grade pipe, and any product where the weld must look perfect. As noted previously, Gas Metal Arc Welding (MIG) and Tungsten Inert Gas Welding (TIG) are the two most widespread types of automatic arc welding.

Pros & Cons:

* Pros: The most perfect joint look and quality, no spatter, possibility of welding very thin materials.

* Cons: It takes longer than MIG welding, equipment can be more costly.

Automated Resistance Welding (Spot & Seam)

What it is: It is through high electrical current and pressure that this process joins metals. Spot welding, as the name implies, is used to join two pieces at a spot. On the other hand, seam welding is a joining process that results in a continuous line weld.

Why it’s automated: Resistance welding is notable for its high strength and accuracy in timing. Automation is capable of delivering repetitive, perfect timing, and power levels that cannot be achieved by humans. Robots might be employed to apply several welds on a car body, which is done within a very short time.

Best-Fit Uses: The use of spot welding in car body assembly is ubiquitous. Seam welding is used for the production of fuel tanks, barrels, and other containers.

Pros & Cons:

* Pros: A rapid process for sheet metal, no consumables such as gas or wire, an environmentally clean process.

* Cons: Only for parts of overlapping design, equipment is costly.

Automated Submerged Arc Welding (SAW)

What it is: SAW is a robust process that requires high power. It uses a continuously feeding wire electrode, which is immersed under a blanket of granular flux. This flux provides a shielding cover for the weld area, adds alloying elements to the metal, and shapes the weld bead.

Why it’s automated: The very high current levels and heat make human intervention difficult and dangerous in SAW. Thus, it is nearly always done through automated systems or mechanized processes. The machines are big and made for machine control.

Best-Fit Uses: This is the go-to strategy for very thick steel plates. It is commonly found in shipbuilding, building pressure vessels, and large steel structural projects.

Pros & Cons:

* Pros: Very high deposition rates (lays down metal fast), deep weld penetration, excellent weld quality.

* Cons: Limited to flat or horizontal positions, requires flux handling and cleanup.

Automated Laser Beam & Plasma Arc Welding

What it is: These technologies are based on the processes of high energy. Laser Beam Welding (LBW) utilizes a highly focused beam of light. Plasma Arc Welding (PAW) makes use of a super-heated, high-velocity gas jet. Both methods create deep, narrow welds at high speeds. This advanced breakdown of common robot welding types often includes advanced methods like laser welding due to their precision.

Why it’s automated: The speed and precision needed for these automated welding methods demand robotic control, which in turn keeps the operators safe from these high-intensity energy sources.

Best-Fit Uses: They find application in high-tech sectors where they are used for medical components, electronics, and joining different or special metals.

Pros & Cons:

* Pros: Very fast, very low heat distortion, can weld difficult materials.

* Cons: Very high initial equipment cost, requires precise part fit-up.

A Concise Comparison of Automated Welding Processes

Making a choice among these methods can be difficult. The table below gives you an easy way to compare the most common types of automatic welding process at a glance.

| Process | Weld Speed | Initial Cost | Weld Quality/Precision | Material Thickness | Best for… | Flexibility |

|---|---|---|---|---|---|---|

| Auto MIG (GMAW) | High | Medium | Good | Thin to Thick | General Fabrication | High |

| Auto TIG (GTAW) | Medium | High | Excellent | Thin to Medium | High-Precision | High |

| Resistance (Spot) | Very High | High | Very Good | Thin Sheet Metal | Automotive Bodies | Medium |

| Submerged Arc (SAW) | Very High | Very High | Excellent | Thick | Heavy Plate | Low |

| Laser Beam (LBW) | Extremely High | Very High | Excellent | Thin to Medium | Precision Parts | Medium |

The table can help you in making a preliminary choice. For instance, in the case where you need speed for general parts, MIG is the best starting point. If you want a perfect weld on thin medical parts, you should choose TIG without any doubt.

Choosing the Right Automation Level: Fixed vs. Robotic vs. Cobot

After you have chosen the welding process, next comes the automation platform selection. This mainly depends on your production volume and your diversity in design files.

Automatic Welding Machine with a Chuck

When to use it: Use this when you have circular welds, whether it’s small batch, high varieties or high volume. Its ajustable chuck can suit your different sizes of parts. Compared to automation welding with a robotic arm, it’s more affordable and specialized in circular welds. Lontitudinal welding can be added as an option.

* Pros: The absolute fastest cycle times plus the lowest per-part cost.

* Cons: The machine may become useless if it’s a square-shaped weld. It’s limited to circular welding or longtitudinal welding added.

Industrial Robotic Automation

When to use it: This is the default for high-volume production with some variation.

* Compared to above automatic welding macine with a chuck, industrial robots has its advantages of welding rectangular or square frames and very complex parts. Because their welding arm can move freely, it adds their flexibility. But it also needs complex programming. In the market, most of the industrial robotic automation is Mig or Mag because Tig robotic automation welding is very costly and only big manufacturers can afford it. They must be enclosed in safety cells and programmed by trained personnel.

* Pros: Fast, repeatable, and can be re-programmed for different parts.

* Cons: Requires a big footprint, significant safety fencing, and complexity in programming.

Collaborative Robot (Cobot) Automation

When to use it: Cobots work best in low-to-medium volume production with a high mix of different parts. They are designed to work safely near people.

* Pros: Easy to program, often by hand-guiding the arm. They can be moved and set up for new tasks quickly. Safety needs are lower (after a proper risk assessment).

* Cons: They are slower and cannot carry as much weight as industrial robots.

Key Factors in Picking Your Automatic Welding Solution

Choosing the correct machine is a big step and should be approached with care. Here is a checklist of key factors to consider when different types of automatic welding process are being explored.

- Part Material and Thickness: This is the main factor that dictates the choice of the welding process. Aluminum often needs a specialized MIG or TIG process. Submerged Arc Welding is the most ideal for thick steel.

- Production Volume & Part Variety&TIG/MIG/MAG: Orbital welder is the answer for high volume pipes. Or the automatic welding machine with a chuck for any kinds of circular welding. On the other hand, robotics will be the answer for high volume and high variety of complex welding path.

- Weld Quality & Specification Requirements: A farm implement only needs a strong MIG weld, but an aerospace part must pass strict standards, like those from the American Welding Society (AWS D1.1 for structural steel). This will most often need the use of TIG or laser welding.

- Budget & ROI Calculation: The price should not be seen as the only factor; look further. Calculate your return on investment (ROI) based on savings in labor, higher output, and better quality.

- Operator Skill & Training: Who will program, operate, and maintain the system? Usually robot welding needs good training and good understanding of welding skills. While with a orbital welder or automatic welding machine with chuck paticular to circular welds, its programming might be easier.

Taking into account these factors may become a complex task. Partnering with an expert may ease the process of evaluating. For a personalized assessment, check out a custom automation welding solution.

Conclusion: The Importance of Right Choice for Future Manufacturing

The selection of the automatic welding method is one of the vital strategic decisions. This decision involves the combination of the right process (MIG, TIG, etc.) with the proper platform (fixed, robotic, or cobot).

The main decision drivers to note are your production volume, part variety, material, and quality needs. When you accurately consider these points, finding the best answer will be easy.

Turning a manual task into an automated one is more than just a machine process. It involves a long-term investment in your company. It guarantees high-quality products, steady production, and the preservation of a leading position in the market. If you are an advanced manufacturing enthusiast wanting to discover various types of automatic welding process, visit Mecanext.

Frequently Asked Questions (FAQ)

What is the most common type of automatic welding process?

Automated Gas Metal Arc Welding (GMAW/MIG) is the most common.But we are also specialized in Automated Tig Welding.

Can any welding process be automated?

Most common arc and resistance welding processes are easy to automate. More specialized processes could be harder to accomplish. But with modern robots with vision systems, more processes are becoming possible. The range of automatable welding types is always growing.

What is the main difference between automatic and robotic welding?

“Automatic welding” is a general term. It includes “fixed automation” for one repetitive task. Like a automatic welding machine with a welding gun and rotating chuck. And it’s more specialized in circular welding, like pipe, metal hoses, tanks, flow meters etc. “Robotic welding” is a flexible type of automatic welding. It uses a programmable robot arm to do many different weld paths on various parts.

How much does an automatic welding system cost?

The cost varies widely. An automatic welding machine with a rotating chuck for circular welds can cost ranging from tens of thousands of dollars. A complex industrial line with multiple robots can cost hundreds of thousands. The price depends on the robot, welder, safety features, and tooling.

Does automatic welding eliminate the need for skilled welders?

No, it changes their role. Skilled welders are essential. They program the robots, fine-tune the welding parameters, check quality, and do complex welds that are not a good fit for automation. Their skills become even more valuable.