In short: It’s an evolution, not a replacement

Will welders be completely taken over by automation in the future? A machine can never completely replace a welder. Professional welders won’t disappear. The problem is that instead of being a standard job, they will be a thing of the past.

Automatic welding machine will take over the repetitive, low-value tasks, so that welders can focus on work that truly requires their experience and judgment.

For example, when we develop our automated welding machine, our aim is to convert the accumulated experience of skilled welders — including parameter selection, process decisions, and problem-solving methods — into standardized menus and welding programs. Once the parameters are standardized, the operator only needs to select the correct menu without making adjustments during welding. Think of it as a system capable of replicating the expertise of your most skilled welder.

With this, the role of welders shifts positively: from repetitive manual labor to handling new products, optimizing processes, and improving overall quality. This frees them from mechanical tasks and allows them to contribute using their skills and thinking — which is also the driving force for a company’s long-term development.

The future does not hold a possibility of humans fighting against robots. It is rather about humans working alongside automation welding. This team model makes work safer and more efficient.

Automation provides a solution to a pressing issue. The shortage of well-trained welders is the main problem. Automatic Welding Machines take care of the undesired and hazardous jobs. This enables the human welders to perform tasks that require the intellect and skills of an expert. This evolution is about upliftment and not destruction.

Human Skill vs. Robotic Precision

To foresee the upcoming scenario, we have to be aware of what humans and robots can do best. They have various advantages. Discussions about whether welders might be out of job due to automation primarily depend on an understanding of these differences.

Welding Robots and Specialized Automatic Welding Machine are quite good at repetitive tasks. For instance, they can do the same simple joint a thousand times without getting tired. Each weld will be almost in consistent welding quality and exactly the same. This feature is particularly effective on mass production lines with large quantities of the same component. Nowadays, there are also suitable automation welding solution for small batch, high mix products, but mainly limited to circular welds.

Human welders, on the other hand, are excellent thinkers and problem-solvers. We are able to learn from negatives. We can weld in tight spaces. We can fix unique breaks and handle custom projects. For complex jobs and quick changes, human welders still hold the edge. A robot can’t easily figure out a new problem on its own.

The table below illustrates the contrast clearly:

| Criteria | Human Welders | Automation Welding |

|---|---|---|

| Task Type | Great at custom, and complex jobs. | Great at products with certain volume, repetitive jobs. |

| Adaptability | High. Can switch tasks and positions easily. | Low. Needs reprogramming for new tasks. |

| Problem-Solving | Excellent. Can find issues and adjust quickly. | None. Follows pre-set instructions only. |

| Setup Time | Minimal. Can start a new job quickly. | Low to High. Requires programming. But it can store the programming for next time usage. |

| Consistency | Good, but can vary due to fatigue or human error. | Perfect. Produces identical welds every time. |

| Upfront Cost | Low. Requires hiring and standard equipment. | High. Requires a relative large initial investment. |

| Ideal Environment | Flexible. Field repairs, custom shops, production. | Controlled. Factory floors with predictable work. |

The Current State of Welding Automation

Often, people talk about automation in a rather complicated way. What does welding automation genuinely involve on a shop floor now?

Different types of automation are being employed at the moment.

- Industrial Robots: These are big, strapping robots that you see in the advertisement of cars. They are often caged for safety. They work on the large production lines. They are very pricey and need expert programmers to operate them.

- Collaborative Robots (Cobots): Cobots are a new, more flexible type of robot. They are smaller and safer. They are designed to work right next to people. They are easier to use and less expensive. Nowadays, many small to medium firms are making use of them. These automated tools are designed to work alongside them and not replace them.

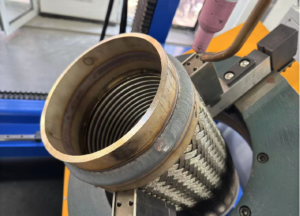

- Semi-Automated Systems: These are tools that help a welder work better and faster. Think of an orbital welder that circles a pipe perfectly. Or a track welder that moves in a straight line. Or a automatic welding machine with a rotating chuck for circular welds. Nowadays, many small to medium manufactures who mainly need circular welds are looking for this kind of automatic welding machine.

Modern manufacturing uses all these systems together. Perusal of the total automation welding solution highlights how these different tools can fit into a business anywhere.

The Welder of the Future: New Roles and Responsibilities

The question “Will welders be replaced by automation?” is in fact about the change of the career. The position is not disappearing. Indeed, it is evolving into something more complex and technical. The welder of the future is less a manual worker and more a tech expert.

The most sought-after welders on modern teams embrace the manual skills and the new technology alike. Managers today are looking for welders who are curious and open to learning. It is now more about managing the process.

Below find the new roles being created at the moment:

The Welding Technician/Robot Operator

This person is the brain behind the robot. They set up the robotic welding cell. They create the program that tells the robot what to do. They watch over the process. They make sure the quality is perfect. This role uses the welder’s knowledge of angles, heat, and materials in a new kind of way.

The Hybrid Welder

This is a skilled welder who does both manual and automated work. They might handle a complex, custom part of a project by hand. Then, they will set up a cobot to weld 100 simple brackets for that same project. This makes them very productive.

The Automation Troubleshooter

When a robot acts up, you don’t go and hit it with a hammer. You need a dual specialist-welding and robotics. This person identifies the problems, makes repairs, and keeps the production line going. That’s a very important and feared skill level.

These new functions often come with better pay. They make the workplace safer. An operator of a robot or automatic welding machine is not exposed to fumes or arc flash through the day. The work is usually more interesting and less physically demanding. The future belongs to welders who are able to fuse traditional welding knowledge with automation expertise.

A Practical Guide: How to Future-Proof Your Welding Career

So, how can you prepare for this change? You can take clear steps today to make sure you have a secure and successful career for years to come. It’s not about fearing if welders will eventually be replaced by automation. It’s about getting ready for the opportunity.

Here is a practical guide to stay ahead.

- 1. Embrace a Technology Mindset: The first step is to change how you think. See automation as a powerful tool that you can master. Don’t see it as a threat to your job. Be curious and open to learning new things.

- 2. Seek Out Training on Automated Welding Systems: You don’t have to become a computer scientist. Many community colleges and trade schools now offer courses on robotic programming. Robot makers like Fanuc and KUKA also have training programs. Learning the basics of operating these systems makes you very valuable.

- 3. Develop Your Core Welding Skills: As robots take over simple welds, expert manual skills become even more important. Get great at welding difficult parts. Master complex, out-of-position welds. These are tasks that robots can’t do well.

- 4. Learn Basic CAD and Blueprint Reading: Modern fabrication starts with a digital file. Understanding how to read digital blueprints helps. Using basic Computer-Aided Design (CAD) software connects you to the entire manufacturing process.

- 5. Focus on Soft Skills: The welder of the future often works in a team. They manage projects and solve problems. Good communication and teamwork skills are just as important as your ability to lay a perfect bead.

The demand for skilled personnel is vast. The American Welding Society forecasts a need for hundreds of thousands of new welding professionals in the next five years. Those who possess both traditional skills and automation knowledge will be in the highest demand.

Conclusion: A Partnership for a Stronger Future

The question, “Will welders then be replaced by automation?” has a distinct and optimistic answer. It is not a matter of replacement. It is a matter of evolution. The core skills of a welder are more valuable than ever. But the job itself is expanding.

The future of welding is the collaboration of skilled humans and powerful machines. Robots will take care of the dull, dirty, and dangerous work. That way, human welders will be left to use their creativity, problem-solving skills, and advisory to tackle more intricate and fulfilling jobs.

If you are ready to learn and adapt, the opportunities are exciting. The following generation of welders will be technicians, programmers, and problem-solvers. For those wanting to stay at the cutting edge of innovation, a fantastic path forward is exploring advanced manufacturing resources on platforms such as Mecanext.

Frequently Asked Questions (FAQ)

1. Will welding automation cause welder salaries to decrease?

No, the opposite is more likely. Welders who learn to program, operate, and maintain automated systems have special skills. These skills are in high demand and often lead to higher pay. While some low-skill jobs may see pressure, skilled technicians will earn more.

2. Can a robot weld better than a skilled human welder?

It depends on the job. For a simple, straight weld or circular weld done in batch, a robot is “better.” It is faster and perfectly consistent. But for a tricky repair on a farm tractor out in a field, a human welder’s skill and ability to adapt is far better.

3. Is it too late to start a career in welding because of automation?

No, it is a great time to start. The industry has a major shortage of skilled workers. If you begin your career learning both classic welding and modern automation, you will be perfectly positioned for a long and successful career.

4. What types of welding jobs are most at risk of being automated?

The jobs most likely to be automated are those with very repetitive tasks in a factory. Think of someone welding the same bracket on an assembly line all day. These high-volume, predictable jobs in industries like automotive manufacturing are the primary targets for automation.

5. How can a small welding shop afford automation?

Automation is more affordable than ever. Smaller, user-friendly collaborative robots (cobots) and specialized automatic Tig welding machine of circular welds cost much less than large industrial robots. Also, some companies now offer “Robotics-as-a-Service.” A shop can rent a robot for a monthly fee instead of buying it. This removes the big upfront cost.