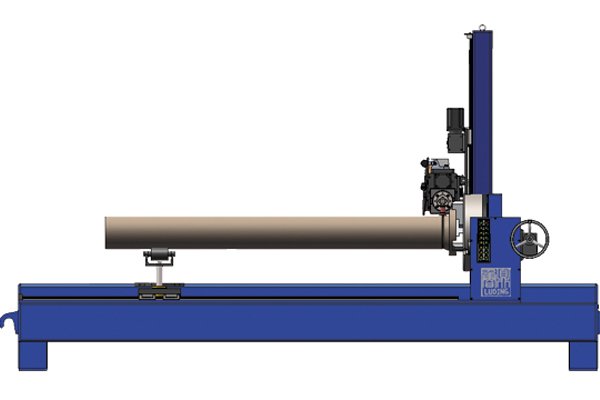

| Model | H1441-T | H1442-T | H1443-T |

| Welding Component Type | Pipe, pipe plate circumferential seam welding and pipe plate fillet welding (optional straight seam welding function) | ||

| Chuck | Center through-hole diameter: 138mm, supports outer diameter Φ20 ~ Φ400mm; Three-jaw self-centering manual lathe chuck | ||

| Positioner | 0° ~ 90° manual positioner; rotation radius: 300mm | ||

| Support | Supports Φ20 ~ Φ400mm; Standard with one set (optional for additional sets) | ||

| Welding Gun Oscillator | Oscillation width: 0 ~ 20mm; Oscillation speed: 0 ~ 20mm/s; Arc stop-side dwell time: 0 ~ 5s | ||

| Arc Length Tracker | Tracking range: 0 ~ 40.0mm; Tracking speed: 0 ~ 6mm/s; Tracking accuracy: 0.2mm | ||

| TIG Wire Feeder | Applicable wire: 1.0mm | ||

| Welding Gun | LD400 water-cooled TIG welding gun; Torch tilt angle: 0° ~ 90° | ||

| Control system | Color touchscreen controller | ||

| Storage | Can store 30 welding processes (optional straight seam welding feature with a storage capacity of 40 processes) | ||

| Welding Layers | Automatic multilayer welding | ||

| Welding Power Source | Panasonic YC-400TX TIG welding power source (optional Panasonic hot wire TIG welding power source) | ||

| Dimensions (LxWxH) | 1500 x 700 x 3.0mm | 2500 x 700 x 3.0mm | 3500 x 700 x 3.0mm |

| Chuck Front-End Travel | 1000mm | 2000mm | 3000mm |

| Total Weight | 1000kg | 1100kg | 1200kg |

| Power input | Welding power source: 30KW/380V/50Hz; Control system: 1.0KW/220V/50Hz | ||

Equipped with TIG welder, arc voltage controller (AVC) and oscillator (OSC).

The automatic wire feeder is equipped with automatic wire retraction and impulse wire feeding functions, ensuring precise and accurate wire feeding.

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province