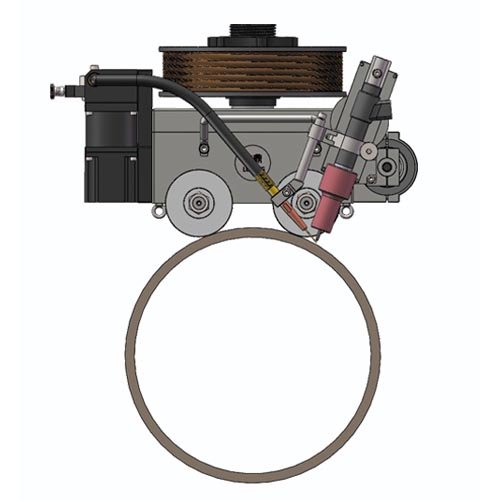

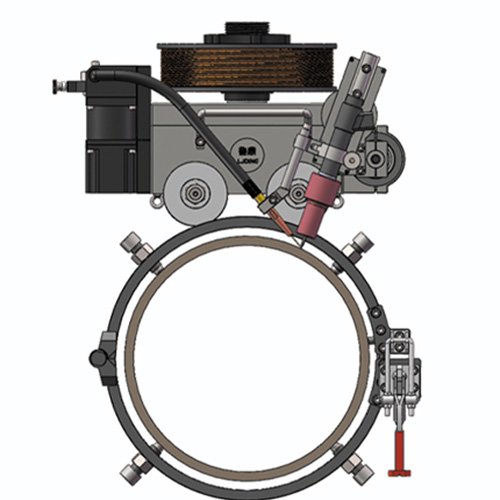

High-performance orbital welding system designed for large-diameter, thick-wall pipes.

Our open-type orbital welding machine integrates Hot Wire TIG technology, offering strong, consistent welds for both magnetic and non-magnetic metals. Ideal for energy, shipbuilding, oil & gas, and pressure vessel manufacturing.

Traditional closed-type orbital welding heads are widely used for small-diameter, thin-wall tube welding, they come with several limitations when applied to larger or more complex welding tasks.

Unlike traditional closed-type orbital welding that use autogenous welding, our open-type design provides:

Supports φ159 mm and above

Designed for large pipes and heavy components, minimizing repositioning needs. Superior performance in high-strength and thick-section welding tasks

Power plant pipe fabrication

Oil & gas pipeline welding

Boiler and pressure vessel manufacturing

Shipbuilding and offshore engineering

Structural pipe assemblies

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province