Automating Nozzle Welding of Pressure Vessel with TIG Technology

In the field of pressure vessel fabrication, most manufacturers have adopted automation for circumferential seam and longitudinal seam welding. These applications are well-suited for automated systems, boosting productivity and consistency. However, one area often neglected in the automation process is the automated welding of pressure vessel nozzles, branch connections, and stub-ins—components that play a critical role in pressure vessels fabrication.

Despite their importance, nozzle welding of pressure vessels is still largely performed manually. This results in high labor costs, inconsistent quality, and slow production—especially when dealing with thick-wall nozzles and multi-pass welds.

The Challenge: Labor-Intensive Nozzle and Component Welding of Pressure Vessels

Nozzles and pipe branches are essential components in any pressure vessel design, enabling fluid entry, exit, and control. Yet in many fabrication workshops, prefabrication of these components, especially thick-wall pipe fittings, remains highly manual.

Challenges include:

- Time-consuming TIG welding for filler passes on thick-wall components

- High dependence on skilled labor for precision welds

- Limited consistency and repeatability

- Difficulties in handling small-batch, high-mix production efficiently

This gap leads to hidden inefficiencies that often go unaddressed in pressure vessel manufacturing workflows.

Mecanext Automated TIG Welding Machine for Pressure Vessels:

Designed for Pressure Vessel Nozzle Welding

To help manufacturers automate these demanding tasks, Mecanext offers a flexible automated TIG welding machines tailored for pressure vessel component welding, including:

- Nozzle prefabrication

- Stub-in and branch pipe welding

- Flange connections and outlet assemblies

✅ Supports a Wide Range of Materials

Handles carbon steel, stainless steel, duplex steel, and alloy steels—ideal for vessels used in oil & gas, chemical processing, food & beverage, and pharmaceutical sectors.

✅ TIG Process for High-Quality Welds

Ensures clean, precise welds with low spatter and excellent heat control—perfect for components where weld appearance and strength are critical.

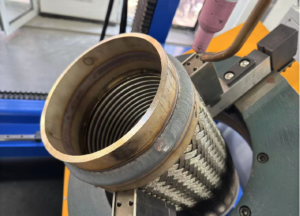

✅ Optimized for Thick-Wall Nozzle Welding

Excels in multi-layer fill and cap passes, offering programmable torch oscillation, adaptive wire feeding, and travel control—greatly reducing manual labor requirements.

✅ Flexible for Small-Batch Production

Quick setup and easy adjustment make it perfect for low-volume, high-variation production environments common in custom pressure vessel fabrication.

✅ Improve Productivity and Reduce Labor Dependence

Delivers consistent, repeatable welds with minimal operator intervention—boosting output and reducing reliance on scarce skilled welders.

Why Automate Nozzle Welding of Pressure Vessels?

While seam welding often receives the spotlight, nozzle and component welding is a major contributor to total man-hours in pressure vessel fabrication. Automating this process with Mecanext’s solution:

- Cuts welding time significantly

- Enhances weld quality and consistency

- Frees up skilled labor for higher-value tasks

- Improves overall production efficiency

This is an often overlooked area of process improvement—one that can generate fast ROI and help manufacturers stay competitive in a tight labor market.

Take the Next Step in Pressure Vessel Welding Automation

Ready to automate your pressure vessel nozzle welding process? Contact Mecanext for a live demo, sample weld trial, or detailed consultation. Our team will help you evaluate integration options for your workshop.

Mecanext – Automatic Tig Welding Machine for Pressure Vessel Fabrication.

1 comment on “Automated Welding for Pressure Vessels: Unlock Precision and Efficiency”

I haven’t checked in here for some time as I thought it was getting boring, but the last several posts are good quality so I guess I’ll add you back to my everyday bloglist. You deserve it my friend 🙂