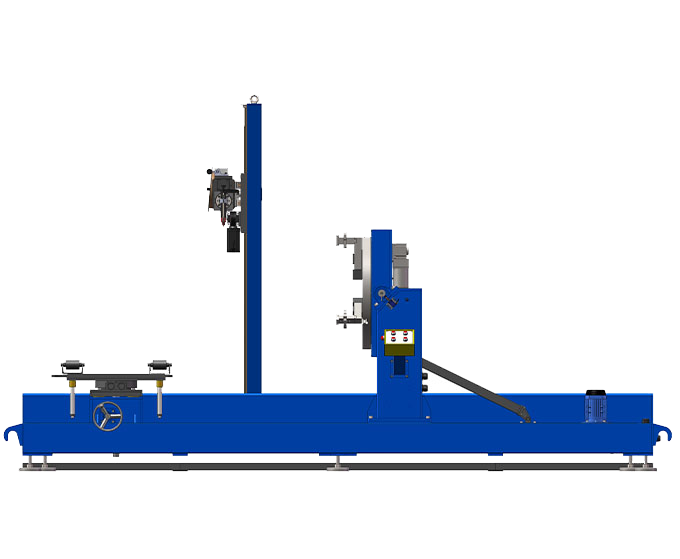

| Category | Specification Detail |

| Model Number | H5082-T |

| Model Welding Component Type | Pipe, pipe elbows, pipe tees, pipe flanges, pipe head flanges (optional direct welding function) |

| Positioner | 0~90° electric positioning; rotating radius 800mm |

| Chuck | Central through-hole 515mm; supports outer diameter Φ100~Φ800mm; three-jaw self-centering electric chuck |

| Support | Suitable for Φ100~Φ800mm; standard with one set |

| Welding Gun Oscillator | Oscillation width 0~20mm; oscillation speed 0~20mm/s; weld side dwell time 0~5s |

| Arc Length Tracking System | Tracking range 0~40mm; tracking speed 0~6mm/s; tracking accuracy 0.2mm |

| Automatic Wire Feeder | Suitable for wire diameter 1.0mm |

| Welding Gun | LD27 water-cooled welding gun; position angle 0~90° |

| Controller | Color touchscreen controller |

| Storage Capacity | Can store 30 sets of welding processes (when equipped with longitudinal welding, storage is 40 sets) |

| Welding Layers | Automatic layer division |

| Welding Power Supply | Panasonic YC-400TX Tig welding power supply (optional with Panasonic hot-wire Tig welding power supply) |

| Operating Stroke (mm) (X Y Z) | 2500 * 900 *30 |

| Front Chuck Stroke (mm) | 2000 |

| Total Weight | 1400KG |

| Input Power | Welding power 30KW/380V/50Hz; control system 1.0KW/220V/50Hz |

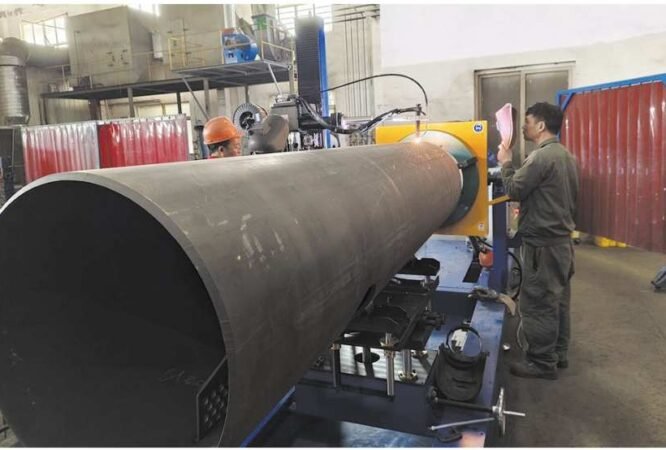

The MecaNext H5082-T is a large chuck automatic welding machine designed specifically for manufacturers handling large-diameter workpieces. Equipped with an oversized chuck and robust fixture system, this machine ensures secure clamping and precision welding for a wide range of applications.

Whether you’re working on industrial tanks, pressure vessels, or cylindrical components, the H5082-T delivers exceptional results in both circumferential and longitudinal seam welding. As a true dual-purpose seam welding machine, it simplifies production by combining two welding modes into one efficient system.

This automatic seam welder for big workpieces is built for high-duty cycles and supports various welding processes, including TIG, MIG, and hot wire TIG. From small batch jobs to continuous operations, it offers the flexibility needed for modern welding automation in heavy industries.

If you’re searching for a seam welding machine for large diameters or a pressure vessel automatic welding machine, the H5082-T provides the capacity, control, and consistency your workshop demands.

Key Benefits:

Key Benefits:Handle bigger parts with ease using the enlarged chuck system

Switch seamlessly between circular and straight seam welds

Achieve consistent results on large pipes, tanks, and vessels

Integrated controls and intuitive HMI for easy operation

Perfect for automated tank welding, pressure systems, and more.

✅ Over 20 years in welding automation

✅ Trusted by global manufacturers

✅ Tailored solutions for custom applications

✅ Remote and on-site technical support

✅ Competitive pricing and fast lead time

Looking to streamline your welding process with one flexible system?

📩 Contact us today for a free consultation or live demo of our automated welding machine.

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province