One-shot automated TIG welding machine for braided metal hoses, delivering higher efficiency, stable weld quality, and oxidation-free internal welds.

One-shot automated TIG welding machine for braided metal hoses, delivering higher efficiency, stable weld quality, and oxidation-free internal welds.

The one-shot welding process for braided metal hoses refers to an integrated welding method in which the metal bellows, braided layer, neck ring, and fitting are assembled and welded together in a single continuous weld seam.

This process eliminates intermediate welding steps and secondary operations, ensuring better weld integrity, improved consistency, and higher overall product reliability.

Key Benefits

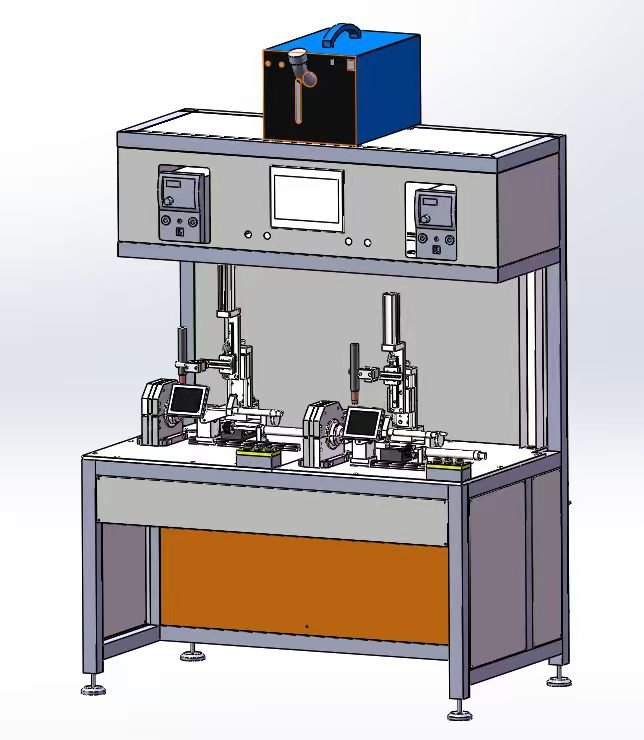

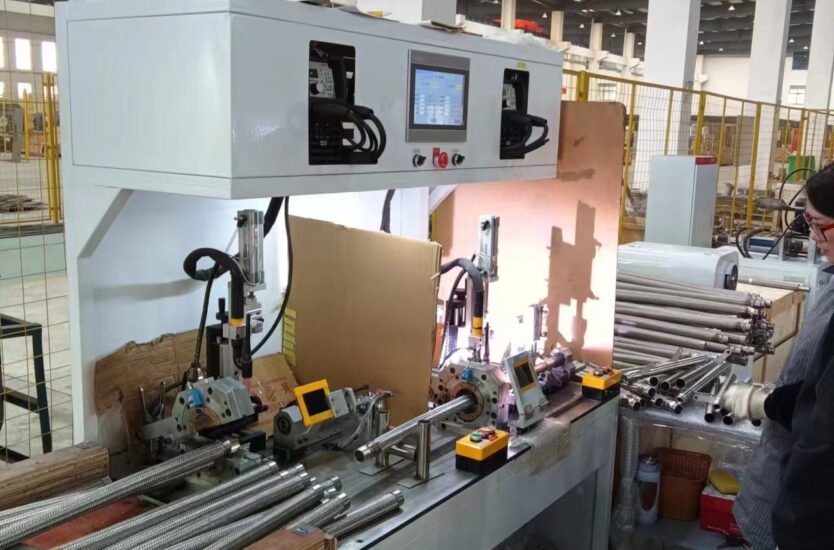

The Braided Metal Hose One-Shot Automated Welding Machine is a dedicated TIG welding system designed for automated one-pass welding of braided flexible metal hoses.

It integrates:

The machine is designed for standing operation, simple setup, and long-term stable production.

|

Welding process

|

TIG Welding

|

|---|---|

|

Welding mode

|

One-shot / one-pass welding

|

|

Automation level

|

Automated welding with manual loading/unloading

|

|

Operator skill requirement

|

Low (SOP-based operation). Operator can weld without any welding skills

|

Process Features

Typical Technical Parameters

Internal: Automatic argon purging

External: Optional external argon shielding

The highest welding efficiency for large volume production

Better welding equality without internal oxidition.

One-shot welding offers better durability, consistency, and service life

Quality ranking (typical):

Seal weld + fitting weld< One-shot welding< Two-pass welding

From fitting design, process selection, production line layout, cycle time planning, to on-site training, we provide end-to-end technical guidance to ensure your target output and quality levels are achieved as planned.

We offer customized solutions covering welding equipment and all upstream and downstream processes. Machine language, functions, and configurations can be tailored to your specific requirements.

We support on-site installation, commissioning, and after-sales service, ensuring the equipment fully meets real production conditions.

This welding method has been widely applied in China for large-volume production of braided metal hose welding. Contact us for free sample demonstration and process validation.

You may send product photos, production volume, application details, and hose diameter to:

sales@mecanext.com

Our technical team will recommend the most suitable automated welding solution based on your requirements.

Standard machines are usually in stock and can be delivered within one week

Customized machines are delivered within one month after order confirmation

We support sample trial welding. Welded samples can be shipped back for inspection, and the welding process can also be demonstrated via live video connection.

All machines are supplied with operation manuals and SOPs, along with installation and commissioning videos.

On-site after-sales service is available. For complete production lines, we also provide professional production capacity planning and workshop layout support.

We, MecaNext, support sample trial welding, live video demonstrations, and full technical consultation.

Please feel free to contact us by 86-19818780849 or sales@mecanext.com

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province