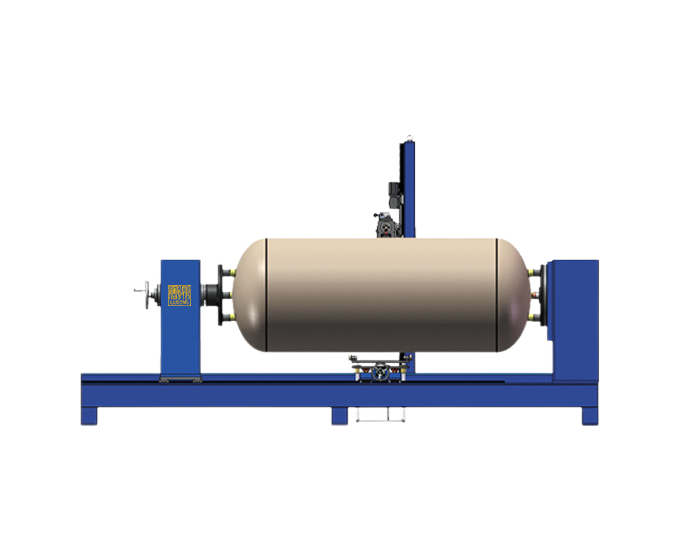

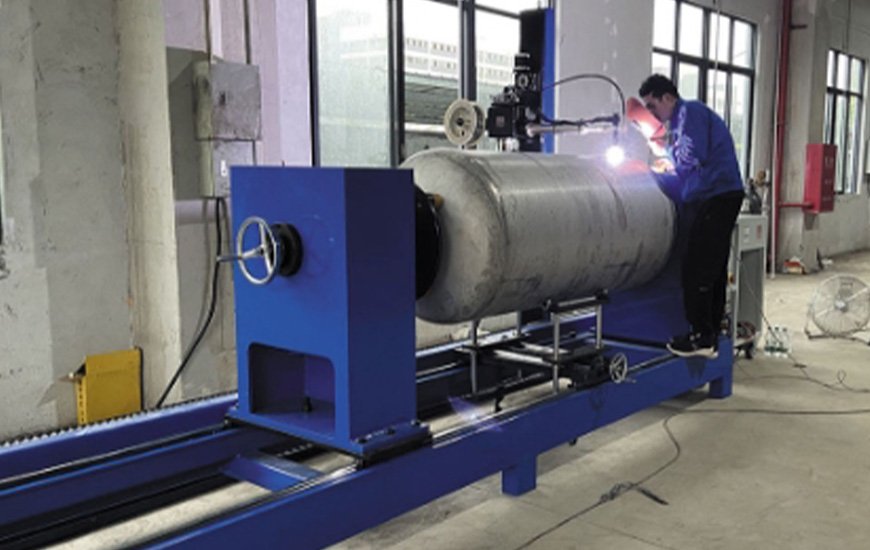

For various tank welds on materials like carbon and low-alloy steel. ldeal for tank end cap circumferential seamsand barrel longitudinal seam.

Optimized for tanks up to 2000mm in length and diametersranging from 400 to 1200mm.

| Specification Model | HZ1220-T |

| Cylinder Specifications (mm) | Diameter Φ400~Φ1200; Length 800~2000 |

| Cylinder Length (mm) | ≤2000mm + 2times standard sealing head length |

| Cylinder Wall Thickness (mm) | 1~6 mm |

| Welding Power Source | Panasonic TYC-400TX Argon Arc Welding Power Source (Optional Panasonic Heat Wire Argon Arc Power Source) |

| Power Supply | Welder 30KW / 380V / 50Hz; Controller 1KW / 220V / 50Hz |

| Welding Angle Adjustment | 0~90° |

| Overall Dimensions (mm) | See detailed drawing |

| Overall Weight | 1800KG |

| Maximum Load | 600KG |

| Control System | Color Touchscreen Programmable Controller |

| Storage Capacity | 40 Welding Processes (30 Circumferential + 10 Longitudinal) |

| Welding Process Count | Automatic Layering |

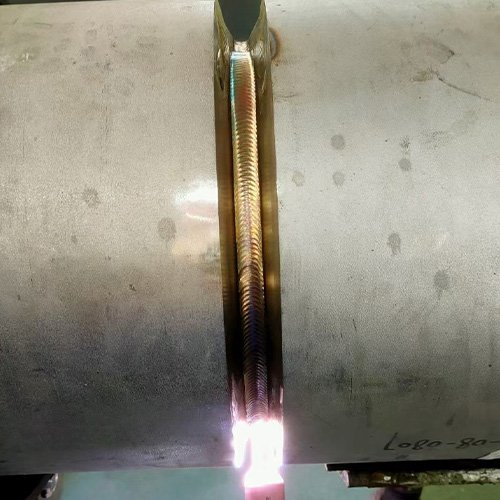

| Welding Oscillator | Oscillation Range 0~20mm; Oscillation Speed 0~20mm/s; Slope Side Dwell Time0 ~5s |

| Seam Tracking Device | Tracking Range 0~40mm; Tracking Speed 0~6mm/s; Seam Tracking Accuracy 0.2mm |

| Argon Arc Welding Wire Diameter | Suitable for 1.0mm |

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province