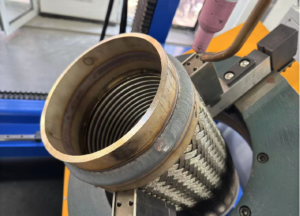

In today’s manufacturing world, automatic welding machines aren’t just a luxury—they’re a competitive advantage. Especially in industries like mechanical seals and seal support systems,metal hoses, expansion joints, pipes where consistency and precision are critical, manual welding has become a costly bottleneck.

One mechanical seal manufacturer learned this first-hand—and their journey from manual welding to a fully automated smart factory is nothing special. They’ve now purchased more than 20 units of our automatic welding machines for use in seal support systems, flanges and precision mechanical components. Why? Because they’ve seen the real, measurable benefits—and they keep coming back for more.

Let’s break down how this transformation happened, and what you can learn from it if you’re considering automation for your own production.

Why Manual Welding Was Holding Them Back in the Mechanical Seal Industry

Manual welding has its place—but in high-precision industries like mechanical seals, it’s often a bottleneck. Before automation, our client faced some very familiar challenges:

🔥 Inconsistent Weld Quality

Even their most skilled welders couldn’t guarantee repeatable results, especially under pressure or long shifts. Mechanical seal components require precision, and manual methods were too vulnerable to human error.

⏳ Low Productivity

Welding even small batches took too long. The client needed to increase output, but hiring more welders wasn’t feasible due to labor costs and the time required to train new staff.

💸 Rising Operational & Training Costs

Mistakes, rework, and downtime added up. Weld failures during quality inspection weren’t just frustrating—they were expensive.

One of our clients in India shared a common issue:

“We have to spend time and money training new welders, but sometimes after the training is finished, the welder just leaves. Then we have to start over again.”

This kind of staff turnover doesn’t just increase training costs—it also introduces inconsistency in weld quality and often leads to delays in delivery, especially when the new welder isn’t yet up to speed.

The First Step Toward Welding Automation

The turning point came when the client decided to trial just one automatic welding machine from us.

They weren’t sure what to expect. The concern, like many manufacturers have, was:

“Can a machine really replace skilled hands and still deliver quality?”

The answer became clear within weeks.

What Happened After the First Machine Was Installed

✅ Better Than Expected Weld Quality

The automatic TIG welding system consistently produced clean, precise welds—even better than manual work. Settings were repeatable, ensuring uniformity across all batches.

🚀 Production Speed Increased Dramatically

One operator could now oversee multiple welds without needing to manually guide each one. The output nearly doubled, and they could meet larger orders without delays.

💡 Easier Training & Safer Operations

The machine interface was user-friendly. Even workers with limited welding experience could be trained to operate it. Plus, with reduced manual handling, workplace safety improved.

From One Machine… to Over 20 Units

The real success came not overnight, but through years of steady growth and continued trust. After proving the value of automation with just one machine, the client began placing repeat orders as their production needs expanded.

- Started with just 1 machine as a trial

- Continued to reorder as benefits became clear

- Over the span of several years, they have now purchased more than 20 units

- Machines are now integrated across multiple production lines for mechanical seal components and seal support systems

Today, their factory runs a clean, high-efficiency welding section—where skilled workers supervise, and automated welding machines handle the precision work.

How This Helped Them Become a Smart Factory

A “smart factory” isn’t built overnight, but automatic welding machines were a critical foundation for them. Here’s what automation made possible:

🧠 Digital Control & Monitoring

Settings, schedules, and diagnostics can be digitally controlled. That means fewer variables, less downtime, and real-time monitoring of each machine.

🎯 Higher Pass Rates

Weld quality improved to the point where rework became rare. Once set the right parameter, the Non-Destructive Testing (like X-ray test/RT and UT etc, can be passed with 100% success. Consistency = fewer inspection failures = happier customers.

💼 Scalable, Future-Proof Manufacturing

With a modular setup, the client can now scale easily. When a new product line is added, they just add another welding cell—no major retraining needed.

What This Means for Other Manufacturers

This isn’t just a one-off story. We’ve seen it play out again and again in industries like:

- Mechanical seals

- Metal hoses and expansion joints

- Pressure vessels

- Pipe and tube fabrication

- Instrumentation and valve parts

- Heat exchangers

- Flow meters and more

Our automation welding isn’t just suitable for relative large volume. If you’re working with high-mix, low-volume production or precision components, automation can give you back control over:

- Lead time

- Cost

- Quality

- Labor risk

And no—you don’t need to jump from zero to 20 machines overnight. The client above started with just one. But it changed everything.

“Why Do Customers Keep Coming Back for More?”

That’s the part we’re most proud of. This client didn’t just buy once—they placed repeat orders over multiple years because the machines worked. That level of trust doesn’t come from marketing—it comes from real results.

Repeat orders are proof of ROI. Here’s why our clients usually expand:

- Machines don’t get tired, call in sick, or make random mistakes

- Each weld is traceable and repeatable

- Operators can supervise multiple machines, reducing labor cost

- Integration into smart production systems is easy

- Remote support and upgrades keep machines working long-term

Key Takeaways

If you’re still on the fence about welding automation, here’s what to consider:

- Start small. One machine can already make a big difference.

- Train smart. Most automatic systems are intuitive, not intimidating.

- Think long-term. You’re not just buying a machine—you’re upgrading your factory’s future.

Ready to Automate Your Welding?

Whether you produce mechanical seals, seal support systems, or other precision components, we’re here to help you transition smoothly into automation.

👉 Contact us for a demo, case study, or ROI estimate.

👉 Want to see the machines in action? We’ll set up a remote or on-site test weld with your part.

👉 Already using automation? Let’s talk about expanding or upgrading to smart controls.

Your competitors won’t wait to automate. Why should you? Explore our automatic welding machines.