Enhance your welding efficiency and quality with our advanced automatic welding machine for metal hoses. Designed specifically for seamless welding of corrugated metal hoses, braids, and neck rings, this cutting-edge solution reduces manual labor costs while ensuring precision and durability. Perfect for industries seeking reliable, high-performance welding automation.

Our advanced automatic welding equipment is perfectly suited for high-quality welding of Stainless Steel Braided Hoses and Flexible Metal Hoses

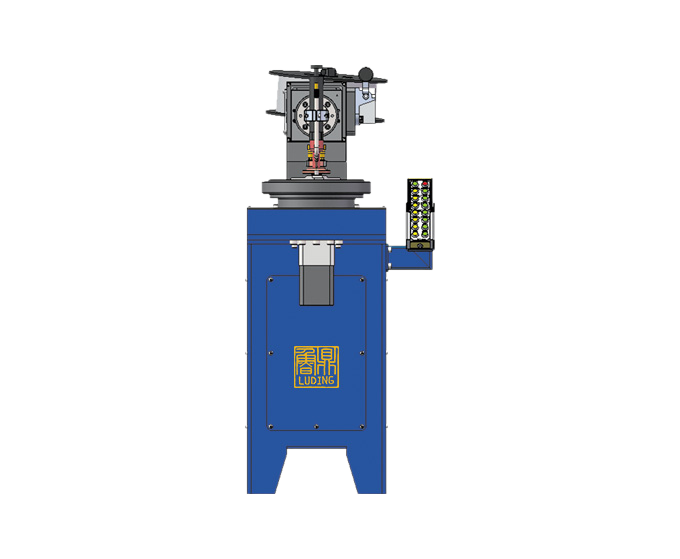

Featuring an integrated design that is both compact and reliable, this system employs a compressing method for weldment fixation, significantly enhancing loading efficiency

| Model | BW70-T Automatic Welding Machine for Metal Hoses |

| Weldable Materials | Carbon steel, Stainless steel |

| Weldable Pipe Diameter | Φ18mm ~ Φ70mm |

| Welding Power Source | Panasonic YC-400TX Argon Arc Welding Power Source (Optional Panasonic Hot Wire Argon Arc Welding Power Source) |

| Power Supply | Welding: 30KW / 380V / 50Hz, Control: 1KW / 220V / 50Hz |

| Rotation Speed | 0.3 rpm ~ 1.5 rpm |

| Shielding Gas | Argon gas |

| Cooling Method | Water cooling |

| Total Machine Weight | 550KG |

| Controller | Color touchscreen programmable controller |

| Storage Capacity | 30 sets of welding processes |

| Welding Layers | Automatic multilayer welding |

| Arc Length Tracking System | Tracking range: 0 ~ 20 mm; Tracking speed: 0 ~ 6 mm/s; Tracking precision: 0.2 mm |

| Wire Feeder | Suitable wire diameter: 1.0 mm |

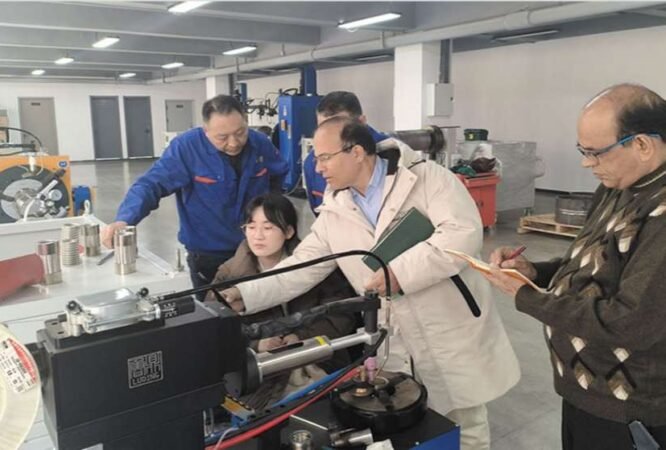

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province