Corrugated Hose End Forming Machine,Precision End Swaging for Welding Prep.

Our machine is designed to deliver precision and efficiency in preparing metal hoses for welding. By seamlessly compressing and thickening hose ends, this advanced machine ensures optimal weld quality, a 100% success rate, and enhanced durability.

| Category | Specification Details |

| Model Number | BWB70 Corrugated Hose End Forming Machine |

| Applicable Pipe Diameter | Φ30~Φ80 (Outer diameter of the pipe) |

| Drive Method | Hydraulic |

| Power Supply | 2KW/380V/50Hz |

| Dimensions | 1000*600*1100 (Length * Width * Height) |

| Weight | Approximately 200kg |

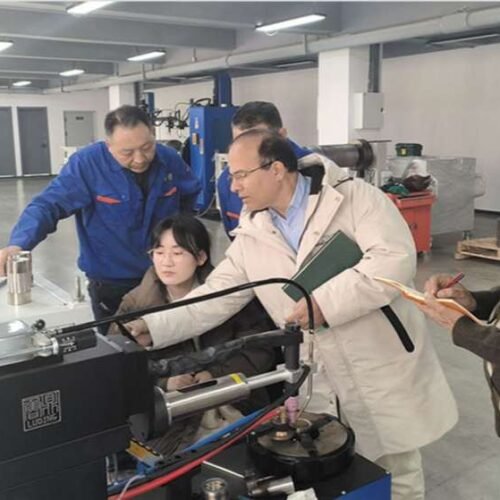

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province