Orbital welding is a welding process that is carried out by a orbital welding head, and it is also known as a machine-controlled welding process. An electric arc spins 360° around a tube or pipe that remains still. This is the way to create very precise and identical welds every time.

The main idea behind this is removing human errors and mistakes. Thus, the quality level that is achieved is hard to get with manual welding. The process guarantees that every weld is almost exactly the same as the one before.

This technology was first used in the aerospace industry. They required it for super-critical operations where even one broken weld was unacceptable. Now, it is widely applied in clean and critical tasks in various industries. It is said to be a highly repeatable process that sets the standards for contemporary building practices.

The Working Mechanism: Core Components and Operation Principles

Orbital welding is a distinct variant of Gas Tungsten Arc Welding (GTAW), commonly called TIG welding.

In TIG welding, you use a tungsten electrode that does not melt. This electrode stays solid and creates an arc. A steady flow of gas like argon protects the metal from oxygen. This prevents contamination and results in a strong, clean weld. Orbital welding adds automation to this process.

An orbital welding system includes several key parts that work together. Learning about these orbital welding system components helps explain how it gets such perfect results.

- Power Supply/Controller: This is the whole system’s “brain.” It contains weld programs that the operator creates and stores them. The controller governs parameters such as current, voltage, and speed. It ensures that each weld occurs under the machine’s precision.

- Weld Head: This is the device that is fastened to the pipe or tube. It carries the tungsten electrode and revolves it around the workpiece. Depending on the task, different types of weld heads are available. The major types are open heads and closed heads.

- Cooling System: Continuous welding generates a considerable amount of heat. A water or air-cooling system circulates through the weld head. This prevents overheating and ensures uninterrupted work.

- Remote Pendant: This is a portable control unit. It allows the operator to select a program, start a weld, and oversee the operation from a distance.

The basic principle is straightforward. First of all, the weld head is clamped to the workpiece. The system fills the area with a protective gas. An electric arc begins at the electrode and the metal. At last, the head moves around the workpiece, exactly tracing the pre-set weld program.

Orbital Welding vs. Manual TIG: The Distinctive Features

The choice of using orbital welding or manual welding is dependent on the needs of the project. For managers and engineers, knowing the key differences is important for making the right choice. What is orbital welding’s true advantage? The benefit is getting rid of the human factor.

Following is a straightforward comparison of the two methods:

| Metric | Orbital Welding (Automated) | Manual TIG Welding (Human) |

|---|---|---|

| Weld Quality | Very high and consistent. Each weld is a perfect copy. | Depends entirely on the skill and focus of the operator. Can be different each time. |

| Consistency | Excellent. The machine does not get tired or lose focus. | Changes with operator tiredness, position, and environment. |

| Speed | Much faster for repeated welds on a production line. | Slower, especially in hard positions like overhead or 6G. |

| Skill Required | Needs an operator, programming, and process. | Needs a welder with high hand-eye coordination and experience. |

| Initial Cost | High first investment in equipment. | Low first cost for basic equipment. |

| Long-Term Cost | Lower cost per weld due to speed, low rejection rates, and less labor. | Higher long-term cost due to slower speeds and higher labor costs. |

| Rejection Rate | Often less than 1% in controlled settings. | Can be 5-10% or higher in very demanding jobs. |

| Data Logging | Built-in. Every weld setting can be recorded for quality control. | Needs separate, manual documentation which can have errors. |

The 7 Steps of The Orbital Welding Process

To really learn what orbital welding is, it is helpful to go through a job beginning to end. As a specialist, I can tell you that the key to success is preparation. The welding machine is the one that does the job, but the operator is the one who thinks.

Here are the seven steps that we carry out for each critical job in the orbital welding process.

- Precision Cutting & Squaring: The process starts with a perfect cut. We use an orbital saw to get a perfectly square, smooth end on the tube or pipe. A bad cut is the most common reason for a bad weld. The surfaces must be perfectly flat to fit precisely.

- Beveling (If Required): In pipes having thick walls (generally thicker than 3mm), a square cut is not sufficient. We must cut a “V” groove, or bevel, at the edges. This creates a channel for the weld to fill. This makes sure the weld penetrates through the entire wall thickness.

- Cleaning & Degreasing: The weld joint and its vicinity must be absolutely clean. We apply special cleaners to get rid of any oil, grease, dirt, and markings. Any debris that gets into the weld can cause it to fail.

- Fit-Up and Tack Welding: The two pieces of pipe are aligned perfectly. For many high-purity jobs (called autogenous welds), there should be no gap between them. We may use small tack welds to keep the pieces in perfect alignment before positioning the weld head.

- System Setup & Programming: The right weld head is attached to the pipe. The operator then chooses or creates a program on the power supply. The program includes the type of pipe material, diameter, wall thickness, and all weld settings.

- Internal Purging & Execution: Before welding, the pipe’s internal space must be filled with a protective gas, for instance, Argon. This is called purging. It defends the weld’s interior from oxygen that would create a rough, damaged surface. After the purge is stable, the operator hits “start” and the machine takes over. It will be done in seconds or minutes.

- Post-Weld Inspection: After the weld has cooled down, it is subjected to an inspection. A quality orbital weld is homogenous and clean. In the most critical jobs in the pharmaceutical or aerospace industry, tools like a boroscope (a tiny camera) are used to check the internal weld. We can also use X-rays to ensure it is perfect.

Critical Applications: Where It’s Essential

Orbital welding is not for every job. It is the best solution when weld quality, cleanliness, and reliability are absolutely critical. And it’s portable which means its easier for you to take it for different projects. Below are the fields where this technique are often applied.

Semiconductor Manufacturing

In this industry, ultra-high-purity (UHP) gas lines are used to make computer chips. Any tiny particle or dirt caused by a bad weld will ruin millions of dollars of product. Orbital welding creates absolutely smooth internal surfaces that prevent contamination.

Pharmaceutical & Biotechnology

In systems that deliver water for medicine or other sterile products, a smooth weld is imperative. A rough manual weld can have tiny cracks where bacteria can grow. The smooth profile of an orbital weld prevents this. This makes systems easy to clean and sterilize. This is a core part of building orbital welding in critical systems.

Aerospace

This is the place where the process was invented. It is used for high-pressure fuel lines, hydraulic systems, and engine parts. The welds’ consistency and reliability are directly tied to flight safety. There is absolutely no room for error.

Power Generation

In nuclear and thermal power plants, thousands of boiler tubes are welded together. These tubes operate under extreme pressure and temperature. A single defective weld can result in a costly shutdown. Orbital welding provides the speed and reliability needed in this work.

Food & Beverage

The food industry, like the pharmaceutical industry, is in need of clean piping. Orbital welds form smooth joints in the stainless steel tubing used for milk, beer, and a range of other products. This ensures that the systems can be cleaned-in-place (CIP) effectively, with no trapped food particles.

Equipment Selection: Open vs. Closed Heads

A major decision in the orbital welding process is the choice of the weld head. The two primary types, open and closed, serve very different purposes. Choosing the right one is critical to success.

Closed (Enclosed) Weld Heads

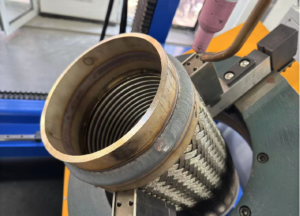

A closed head completely encapsulates the tube ends inside a sealed chamber filled with protective gas.

- Best For: Thin-walled tubes, typically with a wall thickness up to 3-4mm. They are the standard for high-purity jobs in pharma and semiconductor on smaller diameter tubes.

- Pros: They provide the best possible gas protection. This results in extremely clean, repeatable welds with almost no external discoloration or damage.

- Cons: They are limited by the tube’s outside diameter and the physical space around the joint.

Open Weld Heads

An open head is a more flexible, clamp-on device. A torch rotates around the pipe while a gas shield follows the arc.

- Best For: Thicker-walled pipes, larger diameters, and jobs that need adding filler wire to the weld. They are also great for field repairs where clearance is tight.

- Pros: They are highly flexible and can be used on a huge range of pipe sizes and schedules. They easily accommodate filler wire addition.

- Cons: Setup needs more care to make sure the gas shield fully protects the weld puddle as it moves.

As a general rule: for high-purity, small-diameter tubing, a closed head is the gold standard. For larger pipe, construction, and repair work, the flexibility of an open head is essential. As industries seek smarter manufacturing, understanding the right automation welding solution is more important than ever.

Frequently Asked Questions (FAQ) about Orbital Welding

Is orbital welding hard to learn?

It usually takes less time to learn how to operate an orbital welding machine than it takes to become a manual TIG welder expert. The most important skill is not hand-eye coordination. It is learning the process, proper setup, and developing good weld programs. This requires specific training and experience.

What materials can be orbitally welded?

A wide range of materials can be welded. This includes stainless steel, carbon steel, titanium, and nickel alloys such as Inconel and Hastelloy. It can also be used on aluminum and copper alloys. The process is great for materials that resist corrosion or high heat.

Does orbital welding always require filler wire?

No. Many jobs, particularly with thin-walled tubing, use an “autogenous” weld. This means the two tube ends are fused together without adding any extra material. Filler wire is added for thicker-walled pipes to fill a beveled joint and provide reinforcement.

What is the main advantage of orbital welding over manual welding?

The single biggest advantage is repeatability. After a weld program is perfected, an orbital welding system can produce hundreds of identical, high-quality welds. It fully removes the variation and tiredness that come with a human operator. This answers the question of what is orbital welding’s greatest strength.

Can orbital welding be used for repairs?

Yes, it can. Open-style weld heads are particularly useful for repair work. Orbital welding is often used for repairs in critical places like power plants. In these cases, a high-quality, documented weld is required. The system can be used to cut out a damaged pipe section and weld in a new one with high precision.

Conclusion: Embracing Precision and Repeatability

In summary, what is orbital welding? It is more than just a technique. It is a way of thinking about process control that brings unmatched precision, quality, and data to pipe and tube welding.

It moves welding from a manual craft to a controlled, engineered process. The key benefits are clear: superior quality, perfect consistency, and higher productivity. This is especially true in jobs where failure is not an option.

As industries demand higher quality and better documentation, the role of automated processes like orbital welding will only grow. It represents the future of high-tech fabrication. For those looking to explore advanced welding and automation technologies further, you can find a wealth of information and solutions at Mecanext. Check out our automated welding solutions.We have comprehensive automated solutions in closed or open type orbital welder and chuck type automated welding machine.

Contact:sales@mecanext.com and consult the suitable welding solutions for your products!