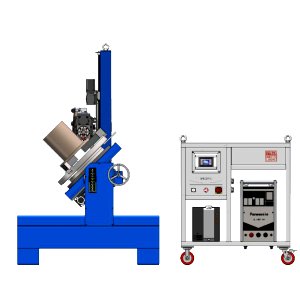

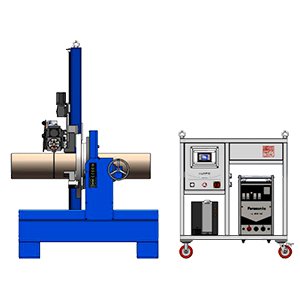

The integrated design of our automatic welding machine ensures a compact, robust, and reliable structure. Its small size and flexibility make it ideal for welding at all angles, providing versatility and efficiency for various welding applications.

| Model | H3660-T |

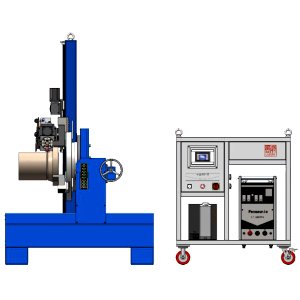

| Welding Component Type | Pipe, pipe plate circumferential seam welding and pipe plate fillet welding (optional straight seam welding function) |

| Chuck | Center through-hole diameter: 360mm, supports outer diameter Φ50~Φ600mm; Three-jaw self-centering manual chuck (optional 3-jaw self-centering electric chuck) |

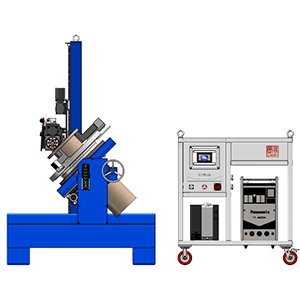

| Positioner | 0°~90° manual positioner; rotation radius: 500mm |

| Welding Gun Oscillator | Oscillation width: 0~20mm; Oscillation speed:0~20mm/s;Arc stop-side dwell time: 0~5s |

| Arc Length Tracker | Tracking range: 0~40.0mm; Tracking speed: 0~6mm/s; Tracking accuracy: 0.2mm |

| TIG Wire Feeder | Applicable wire: 1.0mm |

| Welding Gun | LD400 water-cooled TIG welding gun; Torch tilt angle: 0° ~ 90° |

| Controller | Color touchscreen controller |

| Storage | Can store 30 welding processes |

| Welding Layers | Automatic multilayer welding |

| Welding Power Source | Panasonic YC-400TX TIG welding power (optional hot wire TIG welding power) |

| Operating Travel (X, Y, Z) | 800 × 900 × 30 mm |

| Chuck Front-End Travel | 300mm |

| Total Weight | 1000kg |

| Input Power | Welding power source: 30KW/380V/50Hz; Control system: 1.0KW/220V/50Hz |

Ideal for welding a wide range of products, including braided metal hoses, bellows, expansion joints, pressure pipelines, vessel connections, flow meters, and level gauges, as well as any circular welds.

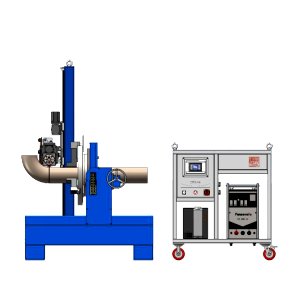

The combination of welding operation arm, positioner, and torch angle adjustment mechanism allows multi-position and multi-angle adjustments of the welding torch.

The operation system of the automatic welding machine features a user-friendly touchscreen interface, facilitating effortless programming.

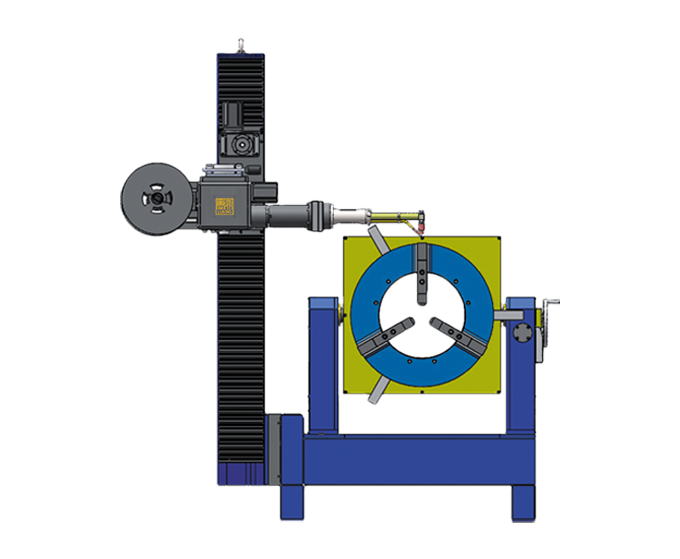

Integrated Design for Precision and Reliability in Automatic Welding Machines

The automatic welding machine features an integrated design with a compact and reliable structure, providing exceptional precision and durability. Equipped with a three-jaw self-centering chuck, the machine ensures precise rotation and positioning, crucial for achieving high-quality welds in various applications.

Advanced Welding Manipulator and Positioner System

This advanced welding system includes a fully integrated three-dimensional welding manipulator arm, a positioner, and an adjustable welding torch angle mechanism, enabling seamless transitions across multiple positions and angles. This combination ensures precise and efficient welding operations, making it ideal for complex welding tasks that demand flexibility and accuracy.

Reliable Cooling and Continuous Operation

To maintain optimal performance, the welding machine is equipped with a forced circulation water cooling unit, ensuring reliable and uninterrupted operation even during extended working hours. This feature helps prevent overheating, guaranteeing consistent quality and efficiency in high-demand environments.

Reliable Cooling and Continuous Operation

To maintain optimal performance, the welding machine is equipped with a forced circulation water cooling unit, ensuring reliable and uninterrupted operation even during extended working hours. This feature helps prevent overheating, guaranteeing consistent quality and efficiency in high-demand environments.

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province