Overcoming the Limitations of Manual Welding in Expansion Joint Production

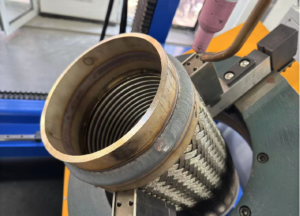

Compared with automated Tig welding, the expansion joint industry faces persistent challenges with traditional manual welding methods. Among these, manual TIG welding for multi-layer corrugated seals remains the most labor-intensive and inconsistent process. It slows down production, affects weld quality, and limits scalability. Despite the emergence of technologies like resistance welding, manual TIG welding is still widely used—especially when high precision and flexibility are required.

However, this reliance on skilled welders creates bottlenecks. Welding multiple circumferential seams by hand not only increases labor costs but also leads to visual inconsistencies, variable quality, and slower delivery times.

How Automated TIG Welding is Revolutionizing Expansion Joint Manufacturing

The introduction of automated TIG welding machines purpose-built for the expansion joint industry is changing the game. These systems are ideal for small-batch, high-precision production environments, offering unmatched consistency, efficiency, and control.

With automation, manufacturers can now produce multi-layer expansion joints with superior welding quality—at a much faster pace. Automated systems remove the guesswork, reduce human error, and create a more repeatable, stable welding process that ensures better aesthetics, structural integrity, and throughput.

Key Advantages of Automated TIG Welding in Expansion Joint Production

🔧 1. Significant Efficiency Gains

Automated systems streamline multi-pass circumferential welding, which is traditionally the most time-consuming task. Weld times are dramatically reduced, allowing higher output with fewer resources.

🔍 2. Consistent, High-Quality Welds

Every weld is executed with machine-level precision. This removes the variability caused by operator fatigue or inconsistent techniques, ensuring uniform weld bead appearance and strength across all products.

💰 3. Reduced Operational Costs

Automated TIG welders reduce dependence on skilled labor and minimize material waste from welding defects. Manufacturers save both on labor and rework, improving their bottom line.

🧑🏭 4. Better Use of Skilled Labor

Instead of spending hours performing repetitive welding, skilled technicians can shift their focus to quality assurance, programming, or process improvement. This leads to more effective workforce utilization.

📈 5. Scalable and Adaptable for Customization

Modern automated welding machines are modular and can adapt to various expansion joint sizes, materials, and designs. Whether producing single-layer or multi-layer joints, the system handles it with ease—ideal for customized or short-run orders.

Driving Innovation with Flexible Automated Welding Solutions

The shift toward automated welding in expansion joint fabrication is not just a trend—it’s a necessity for companies aiming to stay competitive in a global market. As demand for high-quality, high-performance expansion joints grows across industries like power generation, chemical processing, and infrastructure, manufacturers need solutions that combine speed, precision, and flexibility.

Automated TIG welding systems address all three.

The Future: Smarter, Faster, Better Expansion Joint Welding

Automation marks a new era of productivity, quality, and scalability for the expansion joint industry. Forward-thinking manufacturers who embrace automated TIG welding machines are seeing tangible benefits: shorter lead times, improved consistency, and reduced cost per unit.

As industries demand tighter tolerances and higher volumes, automated welding systems are becoming essential for sustainable growth.

✅ Looking to Upgrade Your Expansion Joint Production Line?

Our advanced automated TIG welding machines are engineered specifically for multi-layer expansion joint welding. Whether you manufacture standard bellows or complex corrugated assemblies, our solutions provide the precision, speed, and flexibility you need.

📩 Contact us today to learn how automation can transform your production.

1 comment on “How Automated TIG Welding Is Revolutionizing Expansion Joint Manufacturing”

Greetings from Ohio! I’m bored to tears at work so I decided to check out your blog on my iphone during lunch break. I love the knowledge you provide here and can’t wait to take a look when I get home. I’m surprised at how quick your blog loaded on my mobile .. I’m not even using WIFI, just 3G .. Anyways, fantastic site!