Introduction: Operating with High Risks in Metal Hose Welding

Selecting the right automatic welding machine for your auto metal hose line is a tough decision. A wrong choice can be a problem later. Choosing well is often the key to the success of the entire enterprise.

Significance of the Right Choice

Poor bonds in metal hoses present risks. They can lead to serious leaks through pressure, ruptures, and incomplete product quality. For sectors such as aerospace or chemical transport, the risks of a wrong weld are high. For metal hoses, a weld is more than joining two pieces of metal. They are built to a perfect, leak-proof seal that withstands not only pressure but also bending.

The 3 Decision Fundamentals

Arriving at the right automatic welding machine choice hinges on three main issues. You have to consider these three elementary points with respect to your investment.

- Hose Material & Geometry: This is about the metal alloy in particular, wall thickness, and the hose diameter.

- Required Weld Type & Quality: This point includes the type of weld you want (metal hose fitting welding/ sealing welding/bellows splicing welding) and the welding quality(Whether an oxide-free inner layer is required and what the pressure rating range is.)

- Production Volume & Budget: This is about the number of hoses that you fabricate as well as your projected ROI.

First, Know That Metal Hose Welding Comes with Unique Challenges

Welding metal hoses is a specialized area that has objective difficulties that a regular machine cannot resolve. The first aspect of selecting the right automatic welder is to recognize these hardships.

The Issue of Thin Wall

A corrugated metal hose can be made of very thin wall materials. The wall thickness can be even less than 0.2mm. This makes them sensitive to the amount of heat being utilized. Too much heat can lead to burning through the metal or the metal can warp. This is where the need for accurate heat control comes in.

The Material Factor

Most of the industrial hoses are made up of 300-series of rost resistant steels, namely 304L or 316L. High-performance hoses can be made of alloys like Inconel and Monel. Each metal has its challenges in welding. For stainless steel, carbide precipitation must be avoided. This problem creates weak bonds that are prone to corrosion. In the case of nickel alloys, heat needs to be carefully regulated to maintain their strength integrity. This is achieved through proper machine settings and shielding gas coverage.

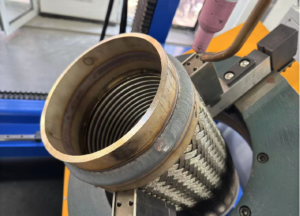

The Perfect 360° Seal

Creating a perfect, consistent weld all the way around a hose fitting is very hard to do by hand. A welder operator may start off well but get fatigued over time. This often leads to unwanted weak points in the welding. Thus, many companies are actively seeking a solution to automate this process. An automated system, like an Automatic Tig Welding Machine for Metal Hoses, accomplishes this task with minimal supervision and ensures every weld is identical and complete.

Automation is also applied while producing the hose tube itself. The longitudinal seam welder unites the flat metal strip into a tube before it is actually corrugated. A seam weld created by an automatic process is always a clean and even line. Manual ones may be uneven and inconsistent.

To see an automatic metal hose welding machine for large diameter in action, check out this short video: Automatic Metal Hose Seam Welding Machine.

The 7 Critical Factors for Your Decision Framework

Making an automatic welding machine selection requires a clear approach. Use these seven parameters as a checklist to analyze your specifications before you engage with vendors.

Factor 1: Material and Wall Thickness

The specific metal and the thickness will categorically define the welding method and the input power which will be required. Thinner sheets are more delicate and thus require low power and gentle handling, while thicker sheets will require much more power to penetrate fully.

- Stainless Steel (<1mm): A low-amperage, pulsed TIG or Laser welder is best.

- Stainless Steel (1-3mm): A standard TIG will work well.

- Inconel/Exotic Alloys: You need a precision TIG machine with advanced controls.

Matching the machine’s power (amperage) with your materials is a first step in learning how to choose the right welding machine.

Factor 2: Hose Diameter and Weld Type

The dimensions of your metal hose and the nature of the weld will largely influence your choice of the machine. The very small hoses that are less than one inch do not require the same tooling as the big ones which are over six inches. It is also advantageous to know if you are going to weld fittings on the end or to make the hose tube itself.

Factor 3: Production Volume

For high volume production, automatic metal hose welding mechine with dedicated molds are typically used to hold the hose, ensuring the highest precision and efficiency. For small-batch production of metal hose, the automatic metal hose welding machine must be adaptable to quick-change of a wide variety of product types.

Factor 4: Required Weld Quality and Certifications

There are many industries that have strict standards for the welding of metal hoses, for example, ISO 10380. If your products must meet these standards, you need welds that are perfect and repeatable. One way might be an automatic welding plant with data logging. The latter will monitor every weld parameter. It is a very effective way of providing the customer with evidence of quality.

Factor 5: Automation Level and Operator Skill

There are different levels of automation. A semi-automatic system might use a positioner to rotate the hose while an operator controls the torch. A fully-automatic system, like an dedicated metal hose welding machine, controls the entire process after a simple setup. Full automation requires a higher initial investment but reduces the need for highly skilled welders. It also delivers unmatched consistency.

Factor 6: Budget and Return on Investment (ROI)

When you choose an automatic welding machine, think beyond the purchase price. You must calculate the total cost of ownership and the return on your investment. An automated system may cost between $20,000 and $50,000 or more. However, it can often reduce weld cycle times by 60-85% and cut defect rates by over 90%. This often leads to a full ROI in just 12 to 32 months.

Factor 7: Facility and Power Requirements

Before you buy, check your workshop. Do you have the necessary power supply for an industrial machine? Do you have enough floor space? Choosing the right welding machine for your business means making sure it fits your existing setup.

Discussing Automatic Welding Technologies for Metal Hoses

1. Automatic TIG Welding Machine for Metal Hose(Rotating-Torch Type)

Automated Circular TIG welding is the most common and versatile solution to the problem of attaching fittings to metal hoses. The mechanism works by engaging the hose and fitting with a clamp while a weld torch rotates around the joint. This solution features lower equipment cost and a simple structure, but because the welding position moves during operation, the weld pool is not completely consistent.

This automatic Tig welding solution for metal hoses is suitable for very long metal hoses and large diameter metal hose automation welding.

2. Automatic TIG Welding Machine for Metal Hose(Rotating-Metal Hose Type)

In this structure, the welding torch remains stationary while the metal hose rotates. This allows the weld pool to remain uniform and consistent throughout the process, typically producing the best internal forming quality.

If you want to see a model of an orbital TIG machine welding a flange onto a corrugated hose, check this video: Stainless Steel Flange to Corrugated Hose Welding Machine.

Uniting It All: A Practical Selection Route

Learning theory alone is not effective; practical experience makes the whole process clearer. This case study shows the process of choosing the right automatic welding machine by the application of the factors we have discussed.

Case Study: A Food-Grade Hose Line

A company needs to make 500 hose assemblies per day for the food and beverage industry. The hoses are 1-inch in diameter with a 0.5mm wall thickness. They are made of 316L stainless steel. The welds must be sanitary and verifiable to meet industry standards.

Step 1: Analyze the Requirements.

- Material: 316L Stainless Steel. This points directly to the TIG process for its clean, high-purity results.

- Thickness: 0.3mm. This very thin wall requires precise, low heat. A dedicated automated welding machine for metal hoses with Tig or Laser Welding is a must to prevent burn-through.

- Weld Type: A circumferential weld joining the hose to a sanitary fitting. Orbital TIG is the perfect technology for this.

- Volume: 500 per day. This is a high-volume operation. The machine needs a high duty cycle, and a fast setup process.

Step 2: Match Technology to Requirements.

Automated laser welding is often used for metal hose below DN25 and it has high requirement for the fitting tolerance. Besides, automated laser welding is not applicable for braided metal hose,but corrugated tube. The clear winner for this application is Automated Circular TIG Welding System.

Step 3: Define Machine Specifications.

The company should look for an automated circular(orbital) TIG welding system. It needs a programmable power supply to save weld schedules. It needs a water-cooled weld head to handle the high volume. It needs quick-change collets for the 1-inch diameter. Data logging capability is also essential for quality control and certification.

By systematically applying these factors, the company can confidently select an automatic welder. This guarantees quality, meets production targets, and ensures compliance.

Beyond the Purchase: Implementation and Support

The process does not finish when the equipment arrives. Your approach in implementing it, as well as the supporting staff you get, are as important as the hardware.

Choosing the Right Partner

Vendor support is as crucial as the machine. Look for a partner who offers installation, optioal on-site training for your team, and responsive technical help. A good partner will work with you to develop the perfect weld parameters for your specific hose assemblies. For instance, specialized suppliers like Mecanext often provide comprehensive solutions. These include machine integration and process development. This ensures you get the most out of your investment.

Don’t Forget Training and Maintenance

Proper training is key to success. Your operators must be comfortable programming the machine, performing daily checks, and identifying potential issues. You should also establish a preventive maintenance schedule for the torch, gas lines, and cooling system. This ensures your automatic welder runs reliably for years.

Conclusion: Making a Confident and Profitable Choice

Deciding on how to choose the right automatic welding machine for metal hose fabrication requires careful consideration. A successful choice depends on a deep understanding of your specific application, including your hose material, diameter, and production volume. By systematically evaluating the key factors outlined in this guide, you can move forward with confidence. The right automatic welding machine is not an expense; it is a powerful investment in the quality, efficiency, and safety of your business.