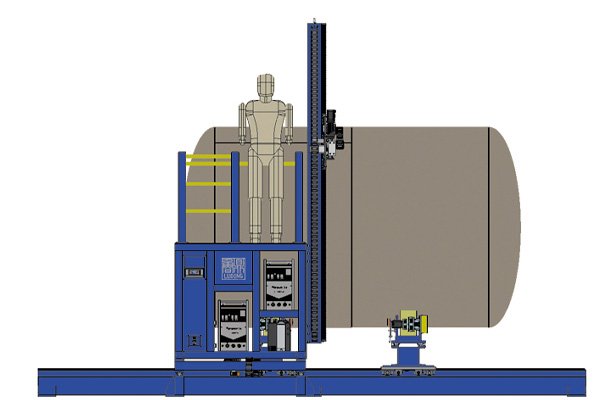

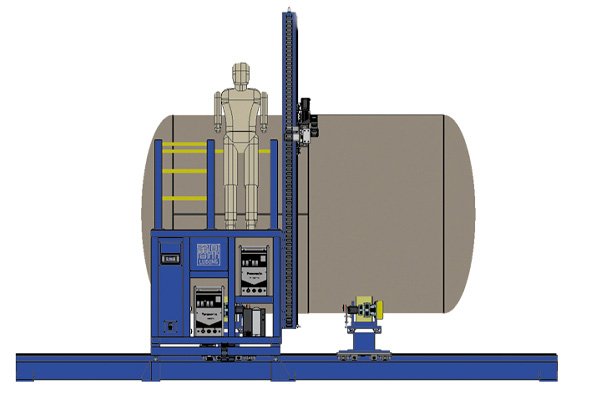

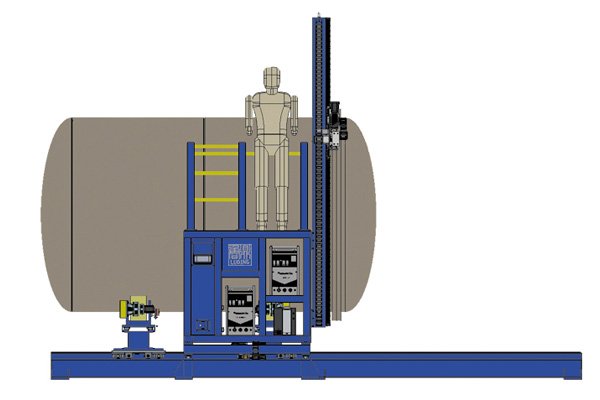

The HZG3050-T is a high-performance automatic welding machine specifically engineered for tank fabrication. It excels in welding both circumferential seams between tank bodies and end caps, as well as longitudinal seams along the tank barrel.

Optimized for tanks up to 5000mm in length anddiameters ranging from 1000 to 3000mm.

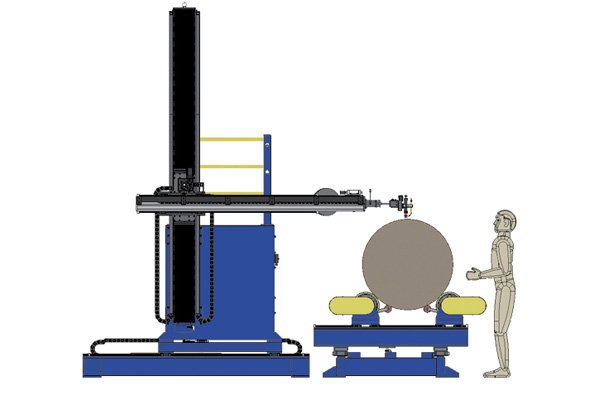

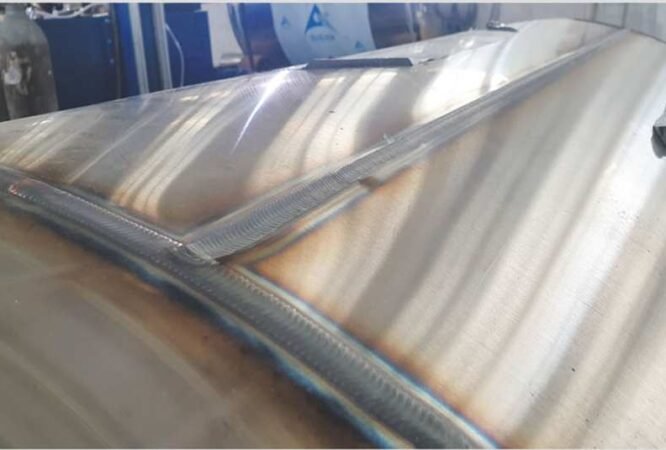

During circumferential seam welding, the weldment is rotated precisely by a CNC-controlled roller frame, while a welding manipulator arm performs the welding operation. This setup ensures uniform, high-quality circular welds, especially in tank fabrication and pressure vessel welding applications.

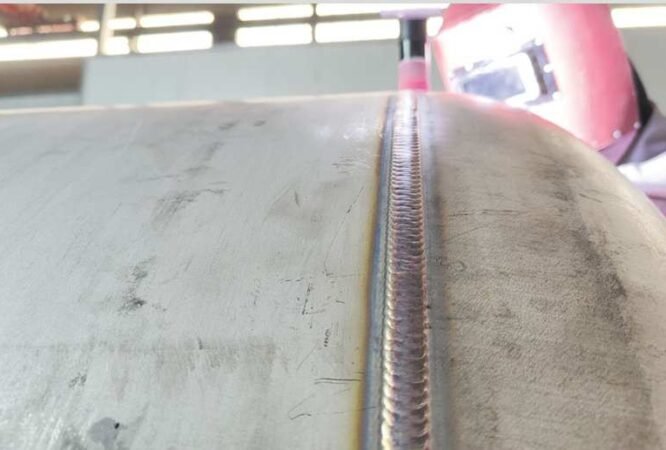

For longitudinal seam welding, the process involves translating the weldment along a fixed welding torch path. This technique is ideal for creating straight, continuous welds on tank shells, delivering consistent results in automatic welding systems.

| Model | HZG3050-T |

| Tank Diameter Range (mm) | Diameter: φ1000 ~ φ3000 |

| Tank Length | No greater than 5000 mm + 2 times the sealing head length |

| Tank Wall Thickness (mm) | 3 ~ 12 mm |

| Welding Power Source | Panasonic YC-400TX Argon Arc Welding Power Source (Optional Panasonic Hot Wire Argon Arc Welding Power Source) |

| Power Supply | Welding: 30KW / 380V / 50Hz, Control: 1KW / 220V / 50Hz |

| Controller | Color touchscreen programmable controller |

| Storage Capacity | 40 sets of welding processes (30 circumferential welds + 10 straight welds) |

| Welding Layers | Automatic multilayer welding |

| Welding Torch Oscillator | Oscillation width: 0 ~ 20 mm; Oscillation speed: 0 ~ 20 mm/s; Hold time at stop: 0 ~ 5 s |

| Seam Tracking Device | Tracking range: 0 ~ 40 mm; Tracking speed: 0 ~ 6 mm/s; Tracking precision: 0.2 mm |

| Argon Arc Welding Wire Feeder | Suitable wire diameter: 1.0 mm |

| Video Monitoring | Optional |

Dual Seam Welding: Performs both circumferential (rotational) and longitudinal (translational) welds on tanks and pressure vessels.

Large Workpiece Support: Handles tanks with diameters from 1000mm to 3000mm and lengths up to 5000mm.

CNC Roller Bed + Welding Manipulator: Ensures precise rotation for circular welds and stable movement for longitudinal joints.

Flexible Torch Configuration: Compatible with TIG, MIG, or hot wire TIG setups depending on project needs.

Heavy-Duty Frame: Rigid structure designed for long-term industrial operation with heavy components.

Multi-Material Capability: Suitable for welding carbon steel, low-alloy steel, stainless steel, and copper.

Pressure vessel manufacturing

Chemical and petrochemical tanks

Water treatment tanks

Oil and gas tank fabrication

Food-grade container welding

Need to automate your tank welding process? Contact us today to request a quote or schedule a live demonstration of our automatic welding machine for different applications.

Every significant collaboration begins with a small ice-breaking moment.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province