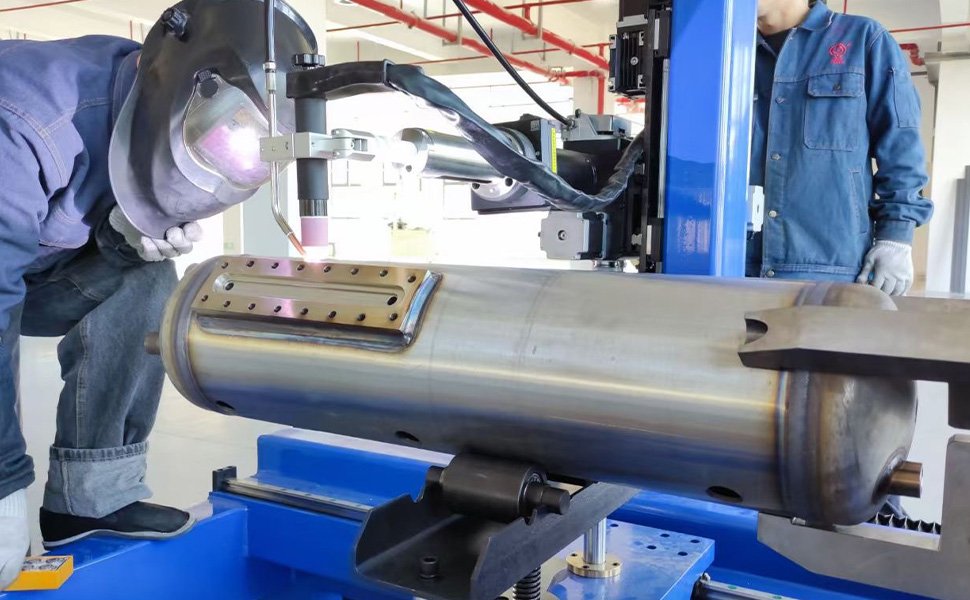

An automatic TIG welding machine is a precision welding system that automates the Tungsten Inert Gas (TIG) welding process, also known as GTAW (Gas Tungsten Arc Welding). It offers high-quality, clean, and spatter-free welds, making it ideal for applications requiring fine weld seams—such as pipes, stainless steel hoses, bellows, expansion joints, flow meters, pressure vessels etc.

Unlike manual TIG welding, automatic TIG welding systems ensure consistent speed, arc stability, and filler control, resulting in repeatable and flawless welds across large production batches. With programmable settings and integrated wire feeding (when needed), they significantly reduce human error and improve welding efficiency.

Below, you’ll find our full range of TIG automatic welding machines, tailored to different product sizes and lengths. Whether you are looking to weld end-sealed hoses, longitudinal seams, circumferential joints or flanges, we have a solution to fit your production needs.

Welding is a highly repeatable and process-driven task—making it ideal for automation. The automated welding machine can translate the best welding conditions and experience of top welders, forming fixed parameters and converting into repeatable, automated processes— delivering higher efficiency and consistent quality.

Automated welder can operate continuously with minimal downtime, significantly increasing output. According to our experience, one automated welding machine can be equal to 2-3 experienced tig manual welder.

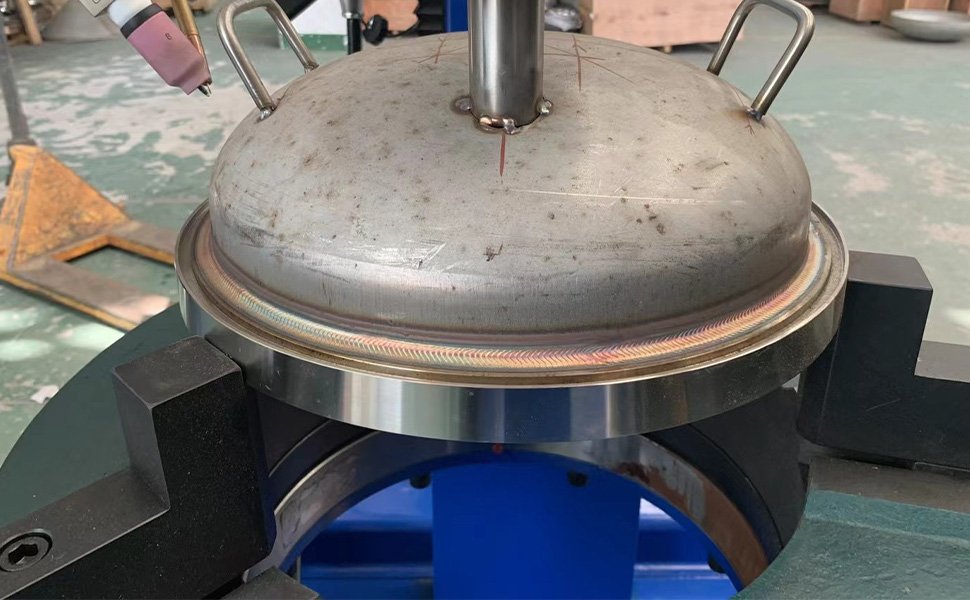

Eliminate human error and achieve uniform welds, even on complex parts or challenging positions. Once setting the right parameter, the success rate of the automated welding system can be 100% and pass UT/RT inspection, pressure test etc.

Skilled TIG welders are increasingly hard to find and expensive to retain. Automated tig welding machines reduce dependence on manual expertise—operators don’t need to be certified welders. With intuitive controls and smart interfaces, even a general worker can manage production after basic training.

Auto welding machine reduces operator exposure to high heat, UV radiation, and welding fumes.

Unlike human welders, machines are not affected by heat, cold, or fatigue. They can operate around the clock in various environments—whether in a hot summer workshop or during cold winter shifts—without compromising performance.

Automation welding is not a one-time purchase—it’s a long-term commitment. You’ll be using the auto welder for years. That’s why it’s essential to partner with a supplier who offers reliable, responsive, and ongoing support and a reliable quality machine.

We don’t just assemble machines or stack external relays which may lead to poor system integration and low reliability. We design, engineer, and optimize through years of real site application. Our welding systems are fully integrated—everything is designed to work together as one solid unit. That means better compatibility, higher stability, and more reliable welding results. Compact design, no messy wiring—just a clean, efficient system that works.

Automation only works if it’s built on solid engineering. You don’t want an automated welder that constantly runs into bugs and disrupts your production. As one of the earliest developers of automated welding, many design flaws still seen in other machines were already eliminated during our early validation stages. Through continuous iteration, we’ve built one of the most optimized and stable solutions available in China.

Our systems are designed with the user in mind: easy to operate, fast to set up, and require minimal training. Even operators without welding experience can run production smoothly. Stores 30 sets of circumferential and 10 sets of longitudinal welding programs. Each program supports up to 8 automatic welding layers, with parameter adjustments available by angular segments for more accurate and consistent circular seam welding.

We combine factory-direct pricing with professional after-sales support, including SOPs, training videos, and real-time remote assistance or onsite technical training. You get global-level automation performance without the high cost of Western brands.

MecaNext machines ensure stable arc control, precise filler feeding, and consistent weld seams. This means less rework, better pass rates, and more predictable production—especially critical for industries with strict standards.

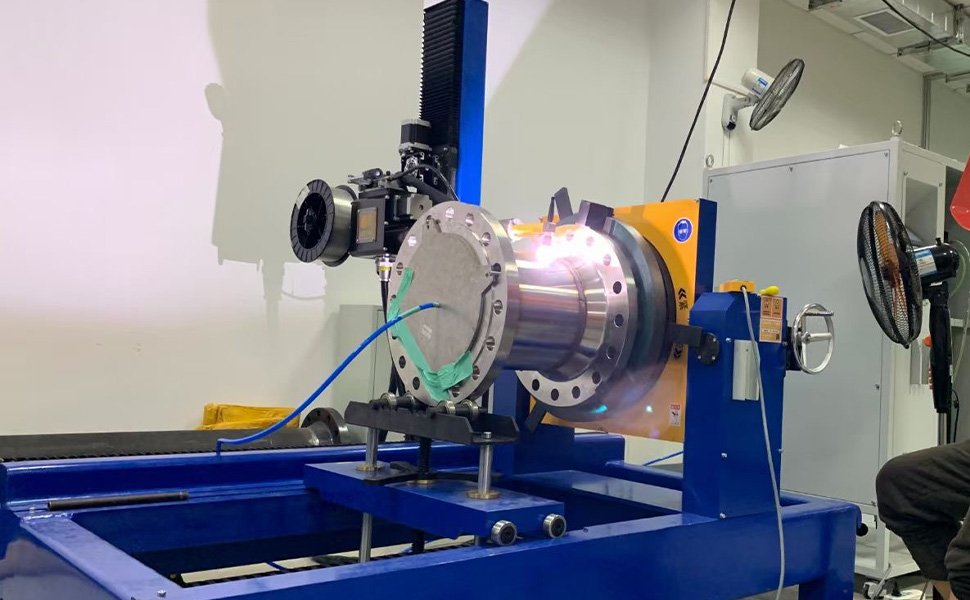

MecaNext TIG Cold Wire and Hot Wire Systems, Cladding Machines, Automatic Pipe Welding Machine, and Orbital welders are the Core of our expertise. With over 20 years expertise in automation welding, our automatic welding systems have been applied and tested in various sectors.

For high-pressure or sanitary piping systems.

End seal and termination welding.

In pressure tanks, ensuring air-tight welds.

Multi-pass long and circular seam welding.

Used in food, beverage, pharma, and chemical tanks.

Precise TIG welding for sensor and sealing performance.

Seamless welding for flanged assemblies.

View Details

View Details

View Details

View Details

View Details

View Details

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province