Introduction

What is welding automation all about? The answer to that is quite short and direct. It involves operating machines, robots, and even smart software for task execution. They mostly go on as long as a little worker helps.

Welding is primarily improving production speeds and quality due to this technology. Moreover, the system makes every weld a replica of the previous one in terms of quality. It is worth mentioning that one of the advantages is creating safer workplaces for workers.

In the modern world, factories are under pressure to produce enough goods and are also struggling to find enough good welders. This is one of the main reasons why learning about welding automation has become essential. This guide will take you through all the necessary aspects.

Let’s Take a Closer Look: Basic Principles

To have a good comprehension of welding automation, one should first think about the manual welding process. A worker who is doing the welding himself, certainly will not be able to keep on doing it forever. When he is tired, it will naturally lead to mistakes. Each time, the melting will be of various quality, which is due to the different speed settings made by the operator.

The automated systems are here to solve these issues. They have a few primary elements that interact with each other. The majority of them are usually the following:

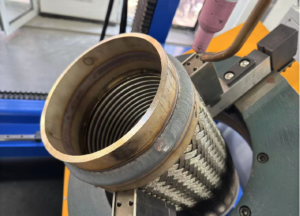

- A robotic arm or machine that moves the torch

- A welding power source and torch

- A computer controller with software

- Sensors to see and track the weld seam

- Tools to hold and move the part being welded

The real purpose of automation is beyond just maximizing speed. It is about obtaining the same perfect end product every single time. Precisely this control over welding makes the technology very beneficial. For a comprehensive an overview of the technology, you can see how these parts create a full system.

The Scale of Automation

Welding automation is not just one product. It is a spectrum. It begins with straightforward paths for use by a welder, right up to fully autonomous robots in the mix. This equates to the probability of a model that meets the specific needs of your shop and budget.

The understanding of these different levels is key. It highlights the fact that you do not have to set up a complex robot cell right from the beginning. Rather than that, you can start with a simple automated manual turn table, for instance.

| Type | Level of Human Involvement | Best For… | Example |

|---|---|---|---|

| Mechanized | High. Operator loads parts and watches the process closely. | Long, straight, or circular welds on large parts. | A track welder that moves a torch along a pipe. |

| Semi-Automatic | Medium. Operator loads and unloads parts, then starts the machine. | High-volume, repeatable parts that fit in a fixture. | A simple robot cell where a worker places parts. |

| Fully Automatic | Low to None. System loads, welds, and unloads parts by itself. | Very high-volume production with little part variation. | An automotive assembly line with multiple robots. |

Assessing the entire spectrum is a pragmatic approach to finding out what is the best fit for your operations. For a broader view of the possibilities in the world of manufacturing, the full range of a company’s capabilities such as those at Mecanext can provide valuable insights.

The “Why”: 5 Key Benefits

The use of this technology provides some considerable advantages for any fabrication business. The considerations besides just speed related to the question, what is welding automation, are very wide. Let’s go through the five main reasons.

Exceptional Quality and Uniformity

A robotic welder hits the same path always. The pace is the same as well as all the settings. There is no fatigue and no distraction. So, human mistakes are eliminated. This results in very few bad parts, a minimal amount of time spent repairing them, and a lower rate of material waste.Enormous Productivity Improvements

Automated systems have a very high welding output rate. The prime advantage is that they can work for much longer periods of time. The “arc-on time” is the actual time spent welding. It can jump from 20-30% in manual work to over 80-90% with automation. This means you can churn out more parts in the same period.Worker Safety Upgraded

Welding can be a dangerous job. When automation occurs, it means the welder stays clear of the noxious fumes, bright arc flash, and physical strain. This can greatly improve shop safety and can reduce the number of welding injuries by hundreds of thousands each year. A safe place to work is the same as a place that is productive.The Move to the Fewer Skilled Laborers Shortage

It is becoming hard to find and retain a competent welder. Automation is a great tool for your existing team. Permitting one capable operator to control several robot cells. Ultimately, your facility boosts production without an influx of new hires.Cost-Effectiveness and ROI Enhanced

The initial expenditure of an automated system may seem high. Nonetheless, the ROI is often very attractive. By looking through the Top Benefits of Welding Automation, you see how lower labor costs, less wasted material, and much higher output lead to considerable savings in the long run.

Is Automation Appropriate for Your Business? A Practical Checklist

The next step after theory is the implementation of “real-world”. Shops usually seek our assistance in identifying if they are ready for automated welding. This checklist can be your helper to decide.

We call it the “3 R’s” of automation readiness. Talk to yourself about parts and processes in these ways.

Repetition: Do you make many of the same parts over and over? Automation works best when doing the same task repeatedly. If your work is mostly one-off custom jobs, manual welding is likely better.

Requirements: Do your customers demand very high levels of quality? For industries such as aerospace, medical devices, and automotive, the precision of automation is often required. It is hard by hand.

ROI (Return on Investment): Is the cost of bad parts, repairs, or high labor a major problem? Calculate how much you spend on these issues. If the savings coming from automation would pay for the system in a reasonable time, it’s a strong point to facilitation.

In addition, think about these other crucial points:

- Are you struggling to find or keep good welders on your team?

- Do you need to increase your output but lack space to add more manual stations?

- Is the improvement of worker safety and employee comfort a key concern for your company?

If you responded with a “yes” to some of these questions, that is an indication. Exploring what is welding automation might be a very good opportunity for your business.

The Human Component: Rethinking the Role of the Welder

A widespread anxiety is about the elimination of welders by automation. But the reality is otherwise. Automation is not about needing fewer skilled people; it is about changing and lifting their role. The future of welding is not about welders being replaced. Instead, it is all about the provision of better tools.

In a highly automated shop, welders take on different and often more valuable roles. Their thorough knowledge of the welding process has additional importance.

The news of welders’ new jobs include:

Robot Programmer/Technician: This person sets up the robot and programs the weld path. They adjust settings to create a perfect weld. They are the brain behind the machine’s strength.

System Operator/Supervisor: An operator often oversees a group of robot cells or automatic welding machines. They make sure systems run smoothly, do quality checks, and handle any issues that come up.

- Maintenance Specialist: Automated systems are complex machines. They need skilled people to do regular maintenance and fix problems to prevent downtime.

The robot is just a tool. It can only do what it’s told. The expertise of understanding metals, weld types, and defect spotting is brought by an experienced person. This knowledge is critical to making any welding automation project successful.

Getting Started: Initial Moves

If you think that automation can be a possible advantage for your shop, the path you need to take is simpler than you might think. The whole operation doesn’t need to be changed overnight.

To begin the journey you should follow this three-step approach:

Identify Your Target Application

Look at your production line and use the checklist from earlier. Find one specific part or process that is repetitive and causes problems. Starting with a single, clear goal is the best way to ensure success.Consult with Experts

Partner with a company that specializes in automation. They can analyze your specific part and process. They will recommend the right type of system and provide a real calculation of your potential return on investment.Plan for Integration and Training

A successful project includes more than just the machine. You need a plan to fit it into your workflow. Most importantly, you need to train your team to operate and manage the new system effectively.

For those ready to take that second step, exploring a dedicated automation welding solution page can show you what’s possible and help you find the right partner.

Conclusion: The Future is Automated, but Skillfully Guided

In conclusion, what is welding automation? It is powerful technology that enhances quality, productivity, and safety in manufacturing. It is not a threat to people with skill; it is the evolution of their craft.

The future of fabrication will go to those who combine human expertise with the precision and power of automation.

Frequently Asked Questions (FAQ)

What is the difference between robotic welding and automated welding?

Automated welding is a broad term for any welding done by a machine. This includes everything from simple track welders to complex systems. Robotic welding is a specific, highly flexible type of automation that uses a programmable, multi-axis robot arm.

How much does a welding automation system cost?

The cost can range widely. A simple mechanized system might be a few thousand dollars. A complete, fully automatic robot cell with safety fences and custom tooling can cost several hundred thousand dollars. The most important factor is the Return on Investment (ROI), not just the upfront price.

Can you automate welding for small batches?

Yes, you can. Traditionally, automation was best for very large production runs. However, modern systems, especially collaborative robots (cobots), are becoming much easier and faster to program. This makes automated welding a good option for smaller and more varied batches of parts.

What welding processes can be automated?

Almost any major arc welding process can be automated. This includes popular processes like MIG (GMAW), TIG (GTAW), Submerged Arc (SAW), and Laser Welding. Choosing the right process depends on your material, part thickness, and the quality you need to achieve.

Will automation take all welding jobs?

No, it will change the nature of welding jobs. Automation is best for repetitive, high-volume work. There will always be high demand for skilled welders for custom fabrication, on-site repairs, and complex projects. Most importantly, skilled people are needed to program, supervise, and maintain the automated systems.