When producing metal hoses, the welding process is one of the most critical steps. The right automated welding solution can significantly impact product quality, production efficiency, and long-term reliability. At Mecanext, we understand that one size does not fit all—different welding processes have unique advantages, and we help you choose the best method for your specific hose assemblies and production requirements.

Traditional manual welding is labor-intensive, inconsistent, and heavily reliant on skilled operators. By switching to automated welding, manufacturers gain:

Recommended Solution: HF50J Metal Hose Welding Machine(Single-Pass Welding)

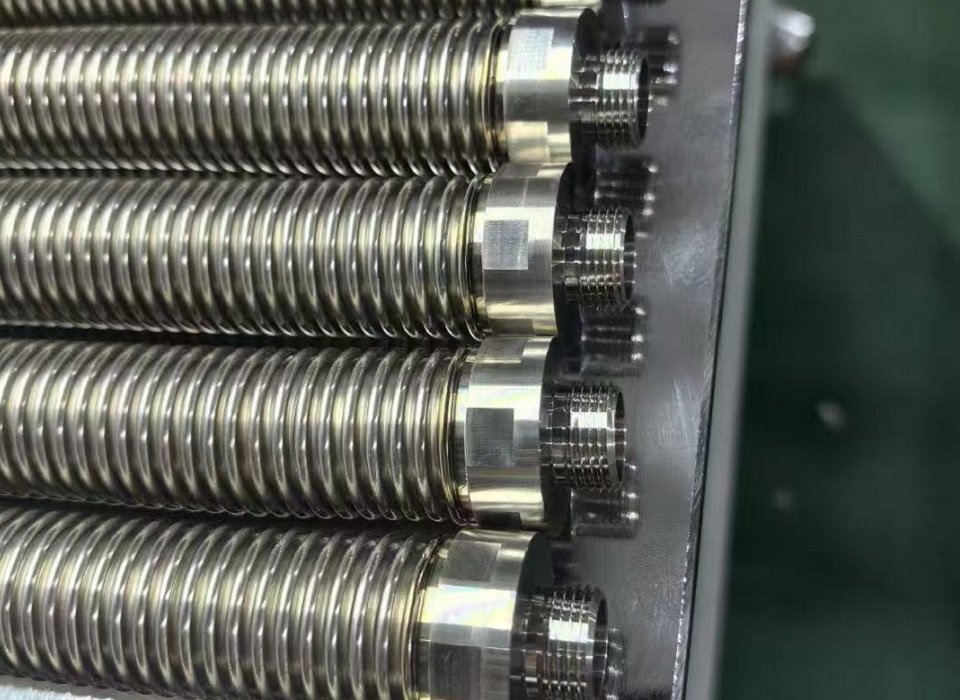

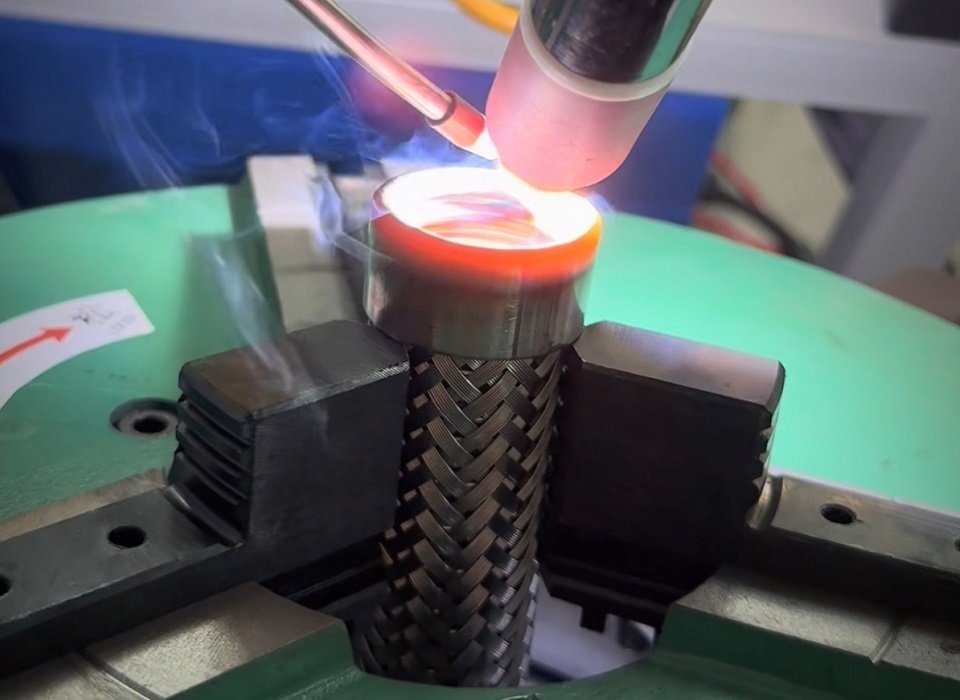

The One-Pass Hose Assemblies Welding process streamlines metal hose fabrication by combining the welding of the corrugated hose, braid, collar, and fitting into a single operation.

How it works:

Instead of separate seal welds and fitting attachment welds, all four components are joined in one continuous TIG weld. This eliminates redundant steps, reduces handling, and maximizes production speed.

Key Benefits

Applications

Ideal for high-volume metal hose production in industries such as automotive, HVAC, and industrial fluid handling, where speed, repeatability, and quality are critical.

Request HF50J Metal Hose Welding Machine(Single-Pass Welding) Demo

Recommended Solution: HF50J Metal Hose Welding Machine

Proper pre-treatment ensures optimal weld quality, smooth external appearance, and flawless internal surfaces.

Key Benefits

Withstands high pressure and intense vibration.

Applications

Vacuum Technology / Vacuum Systems

Medical Equipment & Devices

Food & Beverage Processing

Fire Protection Systems / Fire Safety Equipment

HVAC Systems (Heating, Ventilation & Air Conditioning)

Request Internal & External Two StagesHF50J Metal Hose Welding Machine(2 stages welding) Demo

The Traditional Filler Wire Sealing Welding process is a proven method for batch or small-lot production, offering flexibility and compatibility without requiring component pre-treatment.

Process and Quality

Benefits

Applications

Best for batch production or small-lot manufacturing where multiple hose sizes or fittings are used, and quick setup is required.

When you choose MecaNext, you gain more than just a welding machine—you gain a partner who:

✅ Whether you require high-volume, fast production or flexible, multi-process capability, we can help you find the most efficient, reliable, and cost-effective automated welding solution for your metal hoses.

👉 Ready to discover the best welding solution for your hoses? Contact us today for a free consultation or an online welding demonstration.

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province